People in the softgel capsule production industry know the important role of softgel die roller sets(softgel molds) in the soft capsule production !process. The softgel die roller set has a high cost due to the complex production process and special materials used. Proper roller die maintenance can save the company a considerable amount of expenses.

Do you know how long is the normal service life of a set of softgel die roller set? Has your roller die been corroded and damaged for unknown reasons? Can the die roller be repaired if it is accidentally dented? Read this article carefully and we will answer many questions about soft capsule die roller or toolings for you.

According to the calculation that the softgel encapsulation machine works 8 hours a day and 20 days a month, if there is no damage caused by human error, a set of roller die can be used continuously for at least 12 months. If your die roller needs to be replaced after a few months of use, you need to check whether the use, cleaning and maintenance meet the specifications.

The following are some problems that are more likely to occur in softgel die roller sets and the adverse consequences that may be caused:

1. Injection segment wear

The wedge is in direct contact with the gelatin ribbon, and will constantly rub against the gel ribbon during use, which will cause the teflon coating on the surface of the segment to wear, increase the friction between the gelatin film and the segment, and cause the gelatin ribbon to easily accumulate at the wedge, further causing wavy seams or irregular softgel capsules

2. The die rollers have indentations

Traditional softgel machines are gear-driven, and the die roller alignment needs to be done manually, which is a very delicate step. If the alignment is not done well, once the die rollers are pressurized and starts cutting, the edge of the die roller cavity will leave an indentation on the other roller, causing irreparable damage. Once this happens, the die roller cannot be used or repaired.

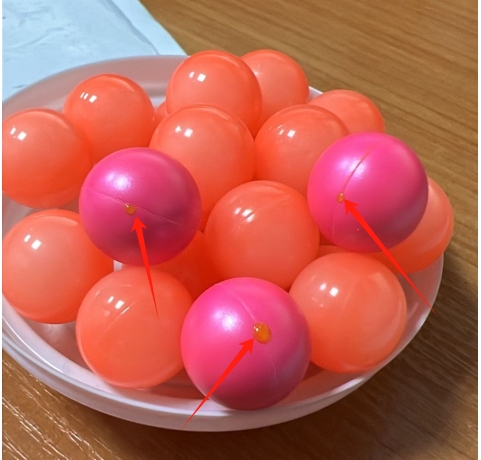

3. There are black spots on the rolle dies surface

The distribution of these black spots is irregular, but most of them are scattered and spread all over the die rollers surface, making the die rollers look very dirty. Some black spots will gradually expand over time. This kind of spot corrosion will not directly cause softgel capsule leakage, but it will cause the capsule seams to be loose, and it is easy to leak after being squeezed or left for a period of time.

4. There are relatively large concave spots on the die rollers surface

These concave spots are deeper and larger, and look like the paint has been chipped off. They are generally distributed on the steps around the rollers’ cavities. These small corrosion spots will leave tiny holes at the seams when the gelatin film is sealed together. When the softgel capsule are just encapsulated from the softgel machine, the temperature at the seams is relatively high, the softgels are very soft, and the fillings will Once the softgel capsules have been left for a period of time, the small holes at the seams will become larger due to the drying and shrinkage of the gelatin film, and the filling contents will leak out. This is why sometimes when The softgel machine is just started, everything seems to be normal, but after a period of production, the capsules will leak.

So what are the causes of these problems? Is there any solution?

1. Injection segment wear

This is a problem that every soft capsule production factory will encounter. Wear is inevitable during normal production. What we can do is to minimize wear. The teflon coating on the surface of the wedge of JANGLI’s softgel die roller is sprayed using a special process. It fits very firmly with the wedge surface and is not easy to fall off. If the wedge is worn, it must be sent back to the manufacturer for re-spraying.

2. The die roller has indentations

New soft gelatin machine operators are prone to poor die roller alignment due to lack of experience, unskilled skills, or failure to correctly master the basic operating specifications of die roller alignment, thereby crushing the softgel die roller. The solution is as follows:

① When training new operators, it is necessary to emphasize the importance of softgel roller dies and its alignment, and focus on training the operation of die roller alignment. In addition, do not place hard parts or tools in and around the softgel encapsulating area during the operation of the softgel capsule equipment to prevent the tools from falling and damaging the softgel roller dies.

② Use professional matching die rolle alignment detection toolings

3. There are black spots on the die rollers surface

Black spots on the softgel die roller surface indicate that the rollers are corroded. It may be caused by using alkaline detergents such as caustic soda to clean the roller dies. If alkaline detergents are not used, it may be that the moisture on the surface of the roller die is not completely cleaned after cleaning, and an oxidation reaction occurs with the air, causing corrosion to the mold.

Solution: Please do not use alkaline detergents to clean the softgel mold. Please use clean water or alcohol to clean the mold. After cleaning, please use compressed air to blow dry the moisture on the surface of the mold, and then use a hair dryer to thoroughly dry the mold. Make sure that there is no water left on the surface of the die rollers. Finally, apply paraffin oil to the thoroughly dried mold surface to isolate the air, and then put it in the die roller box for storage.

4. There are relatively large concave spots on the die rollers surface

The presence of such pits on the mold surface indicates that the small particles in the gelatin liquid have not been filtered clean. When the mold is relatively squeezed, these hard small particles remaining in the rubber will damage the mold.

Solution: After the gelling is completed, the gelling liquid must be filtered, and please do not use gauze or stockings or other filters to filter the gelatin liquid. Such filters are easy to deform, and the mesh will be enlarged, resulting in some small gelatin particles cannot be filtered out. Please use a 100-mesh stainless steel filter, or a professional filter screen as shown in the pictures below, which can filter out 99% of the unmelted gelatin particles.

Some practical suggestions for softgel roller dies use and maintenance:

1. Every time you receive a new mold and before starting the softgel machine to encapsulate softgel capsules, you should carefully check the mold to see if it is scratched or worn, and check whether the mold size and mounting holes match the soft gelatin capsule machine. You can use the following simple tool for inspection.

2. The softgel roller die set is very fragile and easy to damage. Operators need to be very careful when disassembling, cleaning and maintaining the mold. Special mold transport carts can be used.

3. After each batch of soft capsule products is produced, the die rollers must be removed and cleaned and maintained strictly in accordance with the above cleaning process, and placed in a special mold storage warehouse.

4. Not all molds are unrepairable after damage, and not all damages can be repaired. If your softgel mold is corroded or damaged, please be sure to contact the manufacturer or more professional people in time, take photos or videos to let them identify whether it can be repaired.

5. Proper use and maintenance can greatly extend the service life of soft capsule molds. Some of our customers’ molds can be used for one and a half to two years, and even molds that have been used for three years still look clean as new.

6. JANGLI has nearly 20 years of experience in softgel capsule die roller sets and toolings production. We are very professional in softgel die roller design, processing and repair. The factory currently has 10 CNC machining centers dedicated to the processing of soft capsule molds for various softgel machine models. Every year, we provide more than 1,500 sets of molds of different sizes and models to domestic and global softgel capsule manufacturers. If you have any needs or questions about soft capsule molds, you are very welcome to consult us. We can give the most professional advice and solutions. Whether it is a single-step die rollers for animal gelatin soft capsules, a multi-step die rollers for vegetarian softgel capsules, a double-step asymmetric die rollers for paintball production, or a special-shaped die rollers for cosmetic soft capsules, we have a lot of innovation and valuable experience!