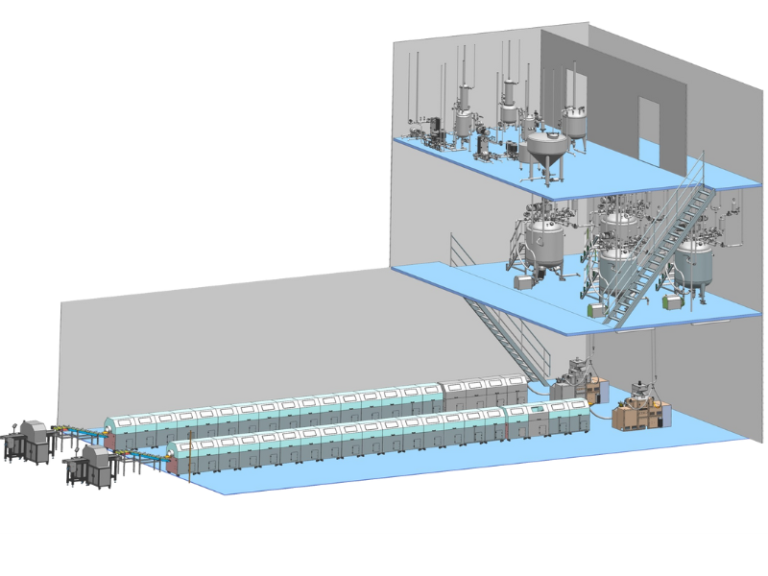

As more industries become aware of the benefits of soft gel encapsulation machines, their use has increased. Although the pharmaceutical industry previously had greater use of soft gel encapsulation machines, other sectors now use them as part of their operations.

However, you must ensure the soft gel encapsulation machine complies with specific requirements for maximum production. You can only accomplish this by conducting a thorough inspection. Working with experts or reputable manufacturers will save you from making costly mistakes when buying soft gel encapsulation machines.

But which essential details should you take into consideration? In this article, I go over why you must conduct a thorough inspection, the critical physical and internal mechanisms to look at, and how to ensure that the soft gel machine complies with industry standards. At the end of the article, you’ll find a few tips on maintaining your soft gel machine.

Why Is Thorough Inspection Necessary?

Every manufacturer wants to buy equipment that will increase output while cutting costs. Hence, you should comprehensively inspect before buying a soft gel encapsulation machine. But is it necessary to perform a thorough inspection?

Yes! One reason is to check to see if the machine’s interface and the various functions available are easy to use. Knowing how to feed the machine’s many functionalities properly is vital if you want it to run effectively. Your machine operators should find it easy to use.

You will know which materials were used to build the soft gel machine by doing a thorough assessment. You can tell the machine’s dependability and durability depending on the material used to make it. It will also be easy to know if it complies with industry standards and regulations.

A comprehensive check is also necessary to assess the effectiveness of the soft gel machine. What are its capacity and speed? How precise and accurate is the dosage system? Can the machine produce the desired capsule size and shape? Is it compatible with the gelatin-containing materials you plan to use?

You don’t want to discover a few days after installation that your soft gel machine is counterfeit or substandard, given the costs of buying one. Buying from reputable manufacturers such as Jangli Equipment is your best bet. Counterfeit or substandard machines are more likely to have unexpected problems and downtime.

What Main Parameters Should You Check?

Alt: Gelatin viscosity testing equipment.

Considering the capital needed to buy a soft gel encapsulation machine, you must ensure you get everything right. The only way to do that is to check the physical components and internal mechanisms thoroughly.

Don’t know what to include in your list? Below, I highlight the various physical and internal mechanisms.

Physical Parameters

I propose carefully examining different physical parameters before buying a soft gel encapsulation machine. These physical parameters will help to confirm if the equipment is of high enough quality, suitability, and effectiveness for your particular needs.

The primary physical features you should pay close attention to are:

- Machine frame: What material was used to build the machine’s frame? An ideal material that most machine manufacturers prefer is stainless steel due to its endurance and resistance to corrosion.

- Capsule encapsulation: Does the machine produce soft gel capsules in the precise size and shape you need for your softgel products? Ask for a brief demonstration to verify that the capsules encapsulated by the soft gel encapsulation machine are flawless.

- Control panel: How user-friendly is the interface and control panel? Your machine operators ought to have no trouble navigating it. Additionally, you should familiarize yourself with the options and functions available.

- Vibration levels: In operation, you must assess the machine’s noise levels. A noisy atmosphere can affect employees’ working conditions, resulting in poor output. Machine wear and tear will result from too many vibrations.

- Molds and Tooling: Which material makes the machine’s tools and molds? The material ought to be durable and wear-resistant. Verify how simple it will be to change the molds(die rollers)for various capsule sizes and shapes. And check carefully if there are damages on the surface of the rollers and segments.

- Safety features: It’s usually recommended that any manufacturing machine must have a stop button for quick shutdown in an emergency. The machine should also have safety guards and sensors blocking access to moving parts to prevent accidents.

- Manufacturer’s certifications: To validate their legitimacy and whether they comply with rules and regulations set by the industry, you might want to look up the manufacturer’s certifications.

Internal Mechanisms

The factors influencing how well internal mechanisms work determine a soft gel encapsulation machine’s functions. I’ve highlighted the major internal systems in the table below and what you should inspect.

| Internal parts | What To Check |

| Gelatin melting/mixing unit | -Does the soft gel encapsulation machine melt the gelatin material effectively and consistently? |

| -To acquire a constant capsule content, ensure the mixing machine can effectively mix the active components with the gelatin solution. | |

| Dosing system | -Which type of dosing pump does the machine have? How does it work? |

| -Verify the pump’s accuracy and reliability in delivering the gelatin material. | |

| -Confirm that the gelatin material is compatible with the exact soft gel machine you intend to use. | |

| -Ensure you can adjust the fill volume simply when you want to produce different-sized capsules. | |

| Drying system | -Assess whether the machine can successfully remove excessive moisture from the variety of gelatin capsules you want to produce by looking at its drying process (tumbler, tray). |

| -Verify the capsules’ potential drying speed. | |

| Cooling system | -Check the cooling system’s effectiveness in quickly hardening the encapsulated soft gel capsules. |

| -Is the machine equipped with precise temperature control systems to avoid capsule deformation? | |

| Sealing system | -Confirm that the capsules have a tight seal by examining the alignment and pressure of the sealing rollers. |

| -Verify that the machine generates a sealing temperature without harming the gelatin capsules. | |

| Cleaning systems | -By carefully cleaning the machine between batches, you can confirm if its internal cleaning system protects against the capsule’s cross-contamination. |

| -The moving parts of the machine can lubricate themselves to increase durability. | |

| Electrical systems | -The machine’s electrical components must conform to safety standards and regulations. |

| Waste collection system | -Assess how well the waste collecting system removes faulty capsules. |

| -The trash collection system keeps good quality capsules from becoming contaminated. |

Is The Soft Gel Encapsulation Machine Meeting Industry Standards?

A machine is only as excellent as its manufacturers. Verify whether the machine complies with industry standards while comparing the various suppliers. I highlight a few industry standards and regulations that the machine you wish to buy should adhere to.

Good Manufacturing Standards (GMP)

GMPs are rules and recommendations that the manufacturing sector uses to guarantee the security and caliber of its products. The production machinery must also adhere to GMP guidelines for that to happen. You can produce safe and high-quality products by ensuring that the machine you wish to buy adheres to GMP standards and regulations.

A company can reduce or altogether avoid instances of error, confusion, and contamination by adhering to GMP requirements. As a result, the customer is shielded against buying an ineffective or hazardous product. Serious repercussions, including recalls, jail time, seizures, or penalties, might result from a company failing to adhere to GMP rules.

GMP regulations address the following issues.

- Sanitation and cleanliness.

- Complaint handling.

- Equipment verification.

- Record keeping.

- Process validation.

GMP is sometimes called cGMP, where “c” stands for current. As a result, manufacturers must adhere to rules by using modern technologies and methods.

Electrical And Safety Standards

The soft gel encapsulation device needs to be UL-certified. It is necessary for the machine’s electrical parts.

The CE Marking is another sign of the electrical safety requirements. The certification shows that the device complies with environmental, health, and safety protection criteria. However, you must have the marking if you intend to conduct business within the European Economic Area.

The soft gel encapsulating machine is free of electromagnetic interference, according to the Federal Communications Commission (FCC). You can use your machine anywhere if you have the FCC mark.

Local Regulatory Requirements

If you want to produce capsules for medicinal use or consumption in the United States of America, your softgel encapsulation machine machine must be Food And Drug Administration (FDA)-compliant.

The machinery must, however, abide by the European Medicines Agency (EMA) in Europe if you operate within the European Union or want to manufacture pharmaceutical soft capsules for sale there.

International Organization for Standardization (ISO) Standards

A non-governmental organization headquartered in Geneva, Switzerland, is the ISO. It is a network of national standard-setting organizations that develops and publishes global standards.

The organization has published more than 25,000 international standards that encompass practically every aspect of manufacturing and technology.

Popular ISO standards include:

- ISO 9001: The international standard known as ISO 9001 outlines the quality management systems (QMS) specifications. It strives to assist businesses in more successfully addressing the demands of their clients and other stakeholders. Building a structure to assure consistent quality in goods and services can help organizations achieve this.

- ISO 14001: Sets standards for an environmental management system (EMS) in ISO 14001. It is a set of guidelines created to assist businesses in improving their environmental sustainability by cutting down on waste and pollution.

Tips On Soft Gel Encapsulation Machine Maintenance

You can watch a brief demonstration of our soft gel washing machine on our YouTube channel.

To guarantee that your smooth gel encapsulation machine functions correctly, you must follow regular maintenance schedules and processes. These regular maintenance routines will assist you in taking care of any concerns as they arise right away.

Here are some pointers on how to perform regular maintenance.

- To guarantee precise measurements and consistent performance, calibrate the soft gel encapsulation machine regularly. Replace any machine parts that are broken, worn out, or misaligned. At the same time, always follow all the manufacturer’s instructions and schedules.

- Regular machine cleaning with suitable cleaning solutions will help prevent the spread of germs and other impurities. To prevent cross-contamination, you should clean after each batch. To get rid of residual gelatin, clean thoroughly each week.

- Make sure your personnel management system is organized effectively. The system helps you hire employees with the necessary expertise and skills to run the machine. Unqualified personnel are more likely to cause unnecessary damage to your soft gel encapsulation equipment.

- Comply with the manufacturer’s recommendations for lubricating moving parts. You can avoid damage to your machine by using the lubricants that the machine’s manufacturer recommends.

- Always remember to keep thorough maintenance logs that include exact information on cleaning schedules, the date that broken parts were replaced, and lubrication dates. You can monitor the machine’s health with the aid of the records. These documents ought to be readily available.

- Always plan for routine maintenance inspections to be carried out by experts from the manufacturer or accredited service providers. Don’t hesitate to ask an expert for help when a machine stops working or for repairs.

Conclusion

It is very crucial that you perform a thorough inspection before buying a soft gel encapsulation machine. Keenly check the physical and internal components to see if they also work.

When evaluating a soft gel encapsulation machine, you must inquire if the manufacturer complies with industry standards and regulations. Fortunately, at Jangli Equipment, we ensure that all our machines conform to current industry standards.

Frequently Asked Questions

- What is the ideal moisture content of a soft gelatin capsule?

A finished soft gel capsule should have a moisture content of 13% to 16%. Store them between 15 and 25°C (59 and 77°F) and 35% to 65% relative humidity to preserve the moisture content.

- Which essential factors should you consider when evaluating a soft gel encapsulation machine?

The machine should be made from high-quality and durable materials. For consistent production, the machine should incorporate precise dosage and system mechanisms in its control processes. A user-friendly interface with intuitive controls for easy input is highly recommended.

The soft gel encapsulation machine should have a design that is easy to clean with smooth surfaces and easy-to-remove parts. The machine should comply with GMP regulations and FDA guidelines. Its manufacturer should be reputable and have certifications for international quality standards such as CE, UL, and ISO.