Most people associate soft gel encapsulation machines with the pharmaceutical industry. The cosmetics and nutraceutical industries come a close second. However, the painting industry has also discovered the immense benefits of using soft gel encapsulation machines in paintball production.

The market study estimates that in 2032 the soft gel encapsulation machine market will be worth $178.39 billion. Soft gel encapsulation equipment’s growth in usage has been attributed to new emerging markets since it is no longer dependent on traditional industries.

Soft gel encapsulation machines have become popular in paintball production. Hence, this article explains paintball production and the factors to consider when choosing a soft gel encapsulation machine. We also give you the process of paintball production, the two types of paintball machines, and their specifications. Finally, we highlight the advantages of soft gel encapsulation machines in paintball production.

What Is Paintball Production?

Paintballs are spherical gelatin capsules filled with dye that burst upon impact. Dyes, polyethylene glycol, and non-toxic, water-soluble compounds are primarily used as paintball fillers. These paint-filled pellets are discharged from a marker, a compressed gas-powered weapon.

The sport of paintball was invented in the early 1960s. It involves using paintballs to try and hit members of the other team. When a paintball hits an opponent, they are out of the game. But don’t worry; the manufacturers of the paintballs use non-toxic and biodegradable paints.

Gelatin to make up the paintball’s outer shell. However, most people are unaware that soft-gel encapsulation machines are used to produce paintballs. Pharmaceutical companies initially produced paintballs since they had the necessary equipment.

In the table below, I highlight the major components of a paintball machine.

| Machine Part | Functions |

| PLC control touch screen | -The machine operator can operate the machine’s die roll, liquid pump, casting drum, and other components and view and control every aspect of the manufacturing process, including output speed. |

| Die-roll | -They make it possible to shape and sculpt the paintballs into 0.68 inch caliber balls. |

| -It is essential since it determines the paintballs’ size and roundness and encapsulation. | |

| -Produces paintballs of the highest quality without worrying about distortion. | |

| Hopper | -Holds the filling material for the intended paintballs. |

| -The fill and shell materials should be melted and maintained at a consistent temperature. | |

| -A hot water jacket built into the hopper ensures continuous heat. | |

| Ribbon lubrication and drive unit. | -An oil roll system is installed on the die-rolls on opposite sides. It enables ribbon lubrication by allowing satisfactory lubrication of paraffin liquid to the lubrication pump. |

| Spreader box. | -It stores the gelatin paint liquid molten after receiving it from the mixing tank. |

| -The die roll’s pocket number determines the spreader box’s size. |

Factors To Consider When Choosing A SoftGel Encapsulation Machine

Most soft-gel encapsulation machines have a PLC controller in the soft-gel encapsulation machine, which manages activities from start to finish with little input from the controller. The controller only needs to enter the manual commands at the beginning of the operations.

You should not worry about the machine’s effectiveness when buying from a respected manufacturer like Jangli Equipment. Our machines have fail-safe mechanisms that can identify and fix any production-line inconsistencies.

However, not all accidents can be prevented by in-built security measures. Therefore, exercise caution when using the machines. Professionals should handle the installation process.

There are a few factors to consider when selecting the soft gel encapsulation machine to fit your demands for paintball production.

- Die rolls for soft gel machines usually range from 80x100mm to 150×250. The die-roll size can be customized to meet your needs, though.

- The quantity of balls in an hour: Most soft-gel encapsulation machines can manufacture 20,000 paintballs per hour at nominal speed. The machine can make 100,000 balls per hour at maximum speed.

- Power generation: A 1.5KW three-phase motor powers a standard soft gel encapsulation machine. You can buy a soft gel machine specially made for you that generates 16KW of power.

- High filling accuracy in a soft-gel machine is what you want. The filling accuracy of a standard model is 1.5–2.0%. Our soft gel machines have a PLC control panel that you can use to boost the machine filling capacity significantly.

A demonstration of how one of our paintball-making machines operates on our YouTube channel.

The Process Of Paintball Production Using Soft-Gel Encapsulation Machines

Alt: Gelatin melting system.

The ingredients used to make paintballs are biodegradable. Gelatin and paint both readily dissolve in water and leave no residues. Put on gloves, goggles, masks, protective clothing, covered shoes, and other safety gear before making paintballs.

We explain the production process of paintballs.

- Weighing And Melting Ingredients

After weighing the ingredients, add them to the melting tank. Polyethylene glycol and water-based paints are the key components most paintball manufacturers use.

Due to the low freezing point of glycol, paintball does not freeze in cold climates. The ingredients are melted in a melting tank at 248°F (120°C).

The total melting and mixing of all the ingredients takes around 30 minutes. Stop mixing once the ingredients have melted, then use a vacuum pump to remove any air bubbles.

- Transfer To The Holding Tank

Pre-heat the holding tank to 185°F (85°C) while the melting process continues. Add the melted ingredients to the mixing tank.

Using connecting pipes, join the holding tank to the encapsulator (spreader box). Turn on the encapsulator and configure the PLC touchscreen so that the encapsulation procedure may begin.

The gelatin mass is forced from the holding tank to the spreader box of the encapsulator by the air-compressed hose in the holding tank. Start the encapsulation procedure after setting up the wedge. The rate at which the encapsulator produces the paintballs depends on how you feed your data.

- Making The Gelatin Ball

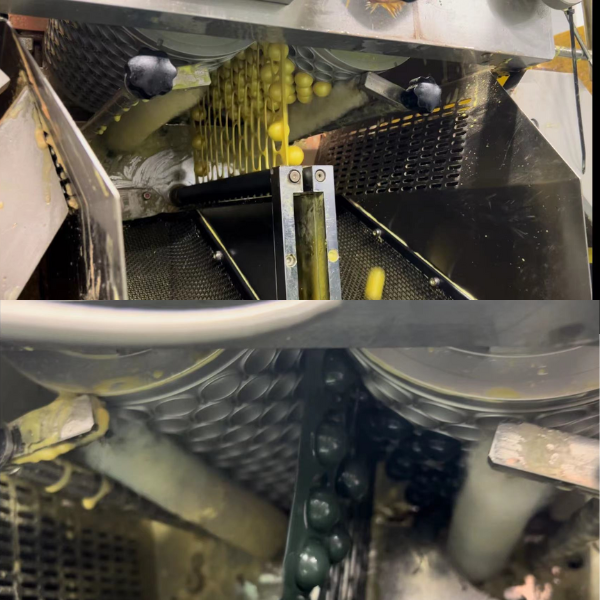

Place two gelatin strips on the encapsulation machine to form the ball. Two counter-rotating drums propel the strips. By lining pockets, the drums also aid in forming a paintball casing.

While injecting an optimal amount of paint into the balls’ casing, the encapsulation machine compresses the gelatin into a pocket. The machine eventually automatically seals the strips, resulting in an enclosed paintball.

- Drying

The paintballs are gently shaken using a tumble dryer machine to cool and solidify them while the gelatin is still warm. The tumbler rotating dryer rotates the balls so they can dry evenly.

The paintballs are then moved to the shelves, which feature movable racks so they may dry out naturally. The time spent in the tumbler and the gelatin concentration affect the air drying time. Ensure the drying area’s relative humidity is between 20 and 30 percent of 75.2°F (24°C).

- Packaging

The paintballs are visually scrutinized for errors after reaching the optimal drying stage. Drop tests are used to determine how brittle the balls are.

The hopper of the packing machine is filled with paintballs that are not faulty. The machine automatically gathers the paintballs and then packages them in bags.

Each container can carry 2410 to 2510 paintballs.

In the Insider YouTube channel, we see how paintballs are made.

Types Of Paintball Machines

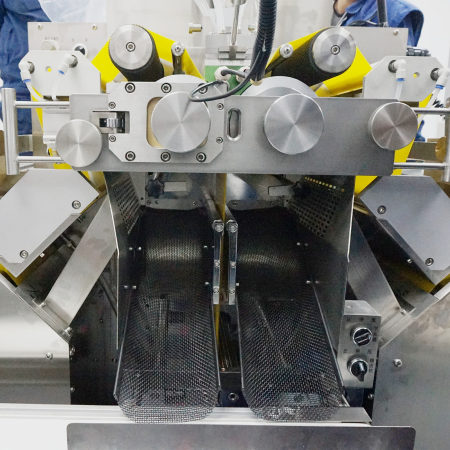

Alt: JL-250II Paintball making machine

Soft gel encapsulating machines are the basis for paintball soft gel filling equipment. We have two different types of paintball soft gel encapsulation machinery for your paintball manufacturing process.

JL-250II Paintball Making Machine

The JL-250II paintball machine can produce about 60,000 balls per hour. It is the ideal machine for you if you want to produce paintballs on a large scale.

The machine’s die rolls have a 150x250mm diameter, which is large enough to produce round balls.

The JL-250II includes an independent chiller that takes the place of the air conditioner, one of its advantages. The chiller cools the gelatin-casting drums, therefore enhancing the chilling process.

The table below shows the specifications of the JL-250Il machine.

| JL-250II Paint Ball Making Machine Specifications | |

| Die roll size. | 150x250mm. |

| Power consumption | 19 KW. |

| Rotating speed | 0~5rpm(step-less speed change). |

| Output | 60,000 balls/hour(cal 0.68’’). |

| Weight of the machine. | 1000 Kgs. |

| Dimension of the machine. | 2050X1200X1850(h)mm. |

JL-15II Paintball Machine

The smallest paintball-making machine so far, the JL-15II, can produce 8,000 balls. The best option for small-scale production is this one.

Not to worry, though, the JL-15II’s die-roller diameter is the same size as the JL-250II at 150mm despite its shorter length.

Only 4 plungers make up the small filler material injection pump of the JL-15II. The machine has an HMI controlling system with a PLC touch screen, making the operation simple.

| JL-15II Paint Ball Making Machine Specifications | |

| Die roll size. | 50x150mm. |

| Power consumption. | 2KW. |

| Rotating speed. | 0~3.5rpm(stepless speed change). |

| Output. | 8,000 balls/hour(0.68’’). |

| Weight of the machine. | 600 KG. |

| Dimension of the machine. | 1700X810X1750(h)mm. |

Advantages of Soft Gel Encapsulation Machines in Paintball Production

Charles Nelson’s idea led Nelson Paint Company to become the first company to manufacture paintballs in 1960. Before the discovery that paintballs could be used for games, they were used to mark the trees that needed to be cut down. Ranchers also used paintballs to brand cattle.

Charles poured paint into a gelatin horse pill to create the first paintball. The original paintballs were filled with an oil-based substance. Using the soft gel encapsulating machine for paintball production has various advantages.

- It lowers the production cost. By buying soft gel encapsulation machines in paintball production, you can produce a lot of paintballs at a lower cost without incurring labor costs. The machine with the lowest paintball output is 8,000 balls per hour.

- Paintball manufacturing with soft-gel equipment ensures uniform fills. No team can point to heavier paintballs as a complaint.

- The soft-gel machines use automatic feeding, filling, sealing, and ejection mechanisms to maintain consistent quality and reduce human error.

Conclusion

Machines for encapsulating soft gels have been adopted by several industries. After the pharmaceutical and cosmetic industries, the usage of soft gel machines in paintball manufacture comes in a very close third.

The JL-15II and the JL-250II are the two paintball guns that Jangli Equipment manufactures and supplies. A production rate of 8,000 balls per hour is possible with the JL-15II. In comparison, the JL-250II can produce 60,000 balls each hour.

Frequently Asked Questions

- How can I make an order for the machines?

Reach out to us for the machine you want. Depending on your requirements, we can advise if you’re unsure about the desired machine.

We give you a quote and aid with the documentation procedure. We assist with installation once the machine has been delivered to your facility. Our machines and equipment come with a one-year warranty.

- Can a production line be connected to the paintball machine?

You can attach the paintball machine to additional equipment to transform a production line.

A gelatin mixing tank, vacuum pump, connecting pipes, conveyor belt, tumbler dryer, and cooling drum are among the supporting equipment you can attach.

- How do I do the maintenance of paintball machines?

Your machine needs proper maintenance to increase its working life. Follow the following rules to ensure proper maintenance of the machines and the personnel without causing any harm.

- When working the machines, the operators should be dressed in protective gear. Safety goggles, shoes, and helmets should be compulsory when operating the machines.

- The machines should only be maintained by qualified personnel. Depending on how the machines are used, maintenance should be performed frequently. Weekly lubrication and greasing of moving parts is recommended.

- Those performing maintenance and the personnel operating the machinery must adhere to all safety regulations.

- Check the equipment’s electrical earthing regularly.

- The employees who run the devices shouldn’t operate them after drinking alcohol

or have taken sleep-inducing medication.