In recent years, the research and development of plant-based gelatin that can be used to make soft capsule film, and the use of plant gelatin to replace animal gelatin has gradually become a new trend and consensus in the softgel capsule industry. The market prospect of vegetable gelatin soft capsules is becoming wider and wider, and it is more and more popular with consumers. If you are new in this veggie softgel production industry, reading this article and you will get almost all information you want to know.

- About Animal Gelatin

Softgel is a packaging method for capsules. It is a capsule made by sealing an oily, fluid liquid or paste medicine into a soft capsule skin(film). The softgel capsule skin(film) is made of edible gelatin, purified water and glycerin mixed in a certain proportion. The gelatin used to make soft capsule skins is mainly derived from animals, so it is also called animal gelatin.

Animal gelatin can be divided into hide gelatin and bone gelatin according to the extraction raw materials. Hide gelatin can be subdivided into cowhide gelatin, pigskin gelatin and fish skin gelatin. Bone gelatin can be subdivided into beef bone gelatin, pork bone gelatin, chicken bone gelatin, fish bone gelatin, etc. Due to the mature extraction process and high output, bone gelatin and hide gelatin are currently the most mainstream gelatin products on the market. However, in some countries and regions with special religious beliefs (such as Islam, Hinduism, etc.), due to dietary taboos, only bovine gelatin can be used. Bone gelatin or fish bone gelatin.

- About Vetegable Gelatin

Although the softgel capsule film made of animal gelatin is harmless to humans, there are also some disadvantages that cannot be overcome in its use:

- Animal gelatin has a high degree of cross-linking and is prone to amino acid cross-linking reactions, causing soft capsule disintegration or dissolution. Reduced;

- If the animal bones used to extract animal gelatin contain germs such as mad cow disease, there is a risk of causing animal-borne infectious diseases;

- It cannot be accepted by some special cultures (Jews, Halal Muslims) and vegetarians;

- Heavy metals, Preservatives and bacteriostatic agents are easily exceeded.

Therefore, in recent years, the research and development of plant-based gelatin that can be used to make soft capsule film, and the use of plant gum to replace animal gelatin has gradually become a new trend and consensus in the softgel capsule industry. The market prospect of vegetable gelatin soft capsules is becoming wider and wider, and it is more and more popular with consumers. At present, the vegetable gelatin developed on the market is starch, and there are two main types: pea starch and tapioca starch. Pea starch (LYCAGEL, developed by Roquette company) cannot be used alone as a raw material for making the outer skin of plant soft capsules. Carrageenan (or Irish algin) must be added to increase its viscosity and gelling properties; Tapioca starch can be used alone as a raw material for making the outer skin of vege-based soft capsules, and can form a film independently without adding carrageenan as an auxiliary.

- What is Tapioca Starch?

Tapioca starch is a powder obtained by dehydrating and drying cassava after starch extraction. It is a powder similar to corn starch or wheat starch. Cassava (scientific name: Manihot esculenta Crantz), one of the world’s three major potatoes (cassava, sweet potato, potato), has different names around the world, called “Tapioca” in Asia, “Manioc” in Africa, and “Manioc” in South America. “Manioca”, “Yucca” and “Mandioa”. In the United States and Europe “Cassava” usually refers to cassava root, while “Tapioca” refers to tapioca starch and other processed products. Characteristics of tapioca starch: Tapioca starch is in the form of white powder. No off-flavor, bland taste with no aftertaste. The paste formed after cooking is clear and transparent. Tapioca starch is very viscous. Tapioca starch is widely used in the food industry and non-food industry in two categories: original starch and various modified starches. Among them, the tapioca starch used to replace animal gelatin to make soft capsule skins is modified starch.

- Where to buy tapioca starch for softgel capsules production ?

Ordinary tapioca starch can be bought everywhere, but the tapioca starch used to make soft capsule gelaint film(rubber) is specially processed and blended, and can only be purchased from professional manufacturers.

The modified tapioca starch used to make soft capsule skins is currently only produced by a Chinese company with secret recipes and patents.

Wuxi JANGLI Machinery CO.,LTD is a professional supplier of softgel encapsulation machines and all other equipment related to softgel capsule production. We cooperated with the Chinese softgel tapioca starch supplier for many years and developed soft gelatin encapsulation machines and equipment according to the characteristics of tapioca starch.

JANGLI has a lot of experiences on tapioca starch softgel production and machine operation. We can help our customers to purchase some(usually 10 bags at the beginning) tapioca starch raw material from the Chinese supplier at a relatively lower price and ship together with softgel equipment for initial machine testing using. We will provide all information and documents needed for the export and use of tapioca starch and the whole standard SOP and our technican will provide on-site teaching of how to use tapioca starch.

And after, customers can choose to keep buying from us or purchase directly from the original supplier in the future.

- Manufacturing Flow Chart of softgels with Tapioca Starch

This is a simple and typical flowchart for the manufacture of starch soft gelatin capsules, without colorants, fragrances, or recycled gelatin substances; the purpose is to help users understand typical manufacturing process differences between animal gelatin and tapioca starch. The whole production procedure is actually roughly the same as animal gelatin softgels, just with some differences in time and temperature.

- What kind of Gelatin Melter(Gelatin Cooking Tank or Gelatin Melting Tank) Need for Tapioca Starch Melting?

For common animal gelatin melting, we usually just need to heat the melter up to around 70°C, but tapioca starch needs much higher temperature to melt and keep it‘s fluidity. And since tapioca starch has much higher viscosity, it needs melter with stronger agitator during melting process. So we summarized the characteristics of tapioca starch gelatin and the corresponding improvement methods of gelatin melting tank equipment as follows:

- The viscosity of tapioca starch is high: the same volume gelatin melting tank needs to increase the stirring power to meet the large torque generated by stirring.

- Tapioca starch has poor liquidity: In order to stir evenly, the stirring speed needs to be increased compared with animal gelatin. Currently it is recommended to set the rotating speed of agitator to 50rpm with VFD control.

- Tapioca starch needs higher melting point: It requires higher temperature to melt. The temperature inside the gel melting tank of tapioca starch needs to be 90°C, and the jacket temperature needs to be 120°C, which compared with animal gelatin is much higher. Jacket water bath heating cannot be used. Glycerin or thermal oil is required to meet the corresponding temperature. Therefore, the medium of the water heater needs to use glycerin or heat transfer oil. Here we use glycerin to heat instead of the traditional water bath.

According to these points, JANGLI developed gelatin melting tanks for vegetable gelatin cooking with different sizes for different output requirements:

- Tapioca Starch Melting Process

The basic ingredients contained in the gel mass with our starch are starch,glycerin, and purified water. The composition rate of the ingredients is as follows:

Tapioca starch: Water: Glycerin= 1:1:0.25~0.3

Here we take a 800L Gelatin Melting Tank(with glycerin heating tank and circulation system) as an example.

- Weigh the tapioca starch, water and glycerin in advance according to the formula proportion, 180KG of starch, 180KG of water, 45KG of glycerin (the materials are vacuum fed to reduce the labor intensity of workers);

- Heat the glycerin heating tank in advance, the preset temperature is 120, and the gelatin melting tank is cleaned and ready for use. When the temperature of the glycerin heating tank rises to 120°C, prepare for production (the hot oil circulation is not turned on);

- First, vacuum the gelatin melter. The pre-weighed purified water and glycerin are sucked in through the top of the tank. After the liquid material has entered, start stirring.

- Continue to maintain a vacuum, and the tapioca starch is sucked into the tank through the bottom of the tank to avoid starch dust generated by the top feed and being sucked away by the vacuum. Starch is fed intermittently to avoid starch agglomeration due to too much feed at one time and increase the mixing time. To extend the gelatinization time; when vacuuming starch, it is recommended to suck it in 4 times. The interval should be based on the uniform mixing of powder and liquid.

- After the starch is fed, the tank is emptied, and the glycerin cycle is started. The material in the tank is heated through the jacket. The entire melting process takes about 3 hours;

- Stirring starts from feeding and ends when the temperature of the material in the tank rises to 95 degrees

- When the actual measured temperature of the gelatin liquid reaches 95 degrees, start keeping it warm and boiling the gelatin liquid. At the same time, calculate the holding time. Keep the gelatin solution temperature at 95-98 degrees and continue stirring for 30 minutes;

- After the heat preservation is completed, reduce the rotation speed to 20Rpm, turn on vacuum degassing, and pump with stirring for 4-5 minutes. Stop stirring and continue vacuuming for 3-4 minutes. Close the vacuum valve and stop vacuuming;

- After one minute, open the release valve, drain it slowly, and observe the temperature of the gelatin solution. A temperature of 82-87 degrees is more suitable;

- Preheat the gelatin service tank to 80 degrees in advance to release gelatin solution;

- When discharging gelatin liquid, you need to use plastic film to cover the gelatin service tank and gelatin liquid discharge valve to prevent the gelatin from condensation due to direct contact with the air. When dispensing gelatin, keep the liquid along the wall of the gelatin service tank as much as possible to reduce the generation of bubbles when dispensing glue.

- How to Choose Appropriate Soft Gelatin Capsule Making Machine for Tapioca Starch Softgel Capsules Encapsulation?

- Measure the size of your workshop.

This is very important. If you want to use the softgel machine for real production not just R&D, you need a room of suitable size to place the soft capsule machine and the softgel shaping tumbler dryers. Different sizes of equipment require different room sizes. For the moment, JANGLI has 5 styles of soft gel capsule filling machines: JL-100II, JL-150III, JL-250II, JL-250III, JL-300III. And the machine size and recommended layout are as follows:

- Determine your softgel capsule production capacity requirements

If your production capacity requirements is 30,000 capsules(8#Oval, 500mg, fish oil) or less per hour, you need the smallest softgel capsule filling machine(R&D Softgel machine);–JL-100II

If your production capacity requirement is 50,000 capsules(8#Oval, 500mg, fish oil) or less per hour, you need a medium size softgel capsule machine.–JL-150III

If your production capacity requirement is 100,000 capsules(8#Oval, 500mg, fish oil) or less per hour, you need a bigger size softgel capsule making machine.–JL-250II

If your production capacity requirement is 150,000 capsules(8#Oval, 500mg, fish oil) or less per hour, you need a big size softgel capsule machine.–JL-250III

If your production capacity requirement is 200,000 capsules(8#Oval, 500mg, fish oil) or less per hour, you need a largest size softgel capsule machine.–JL-300III

If you are not quite sure what type of machine you need, you can contact us JANGLI here to get a quick feedback and we will recommend the most suitable soft gel making machine according to your specified description.

- Determine your budget

Your budget determines the degree of automation you choose for your soft gel capsule making machine; If you have a limited budget, you can choose a larger size soft gelatin machine with a traditional gear transmission system. If you have enough budget, you can choose a soft gel capsule machine driven by a servo system that is simple to operate, relatively small in size but faster in speed.

The traditional soft capsule machine is with gear driving system, which will produce vibrations during the transmission process, affecting the stability and operating speed of the machine. In addition, the alignment of the die rollers and the adjustment of the medicine injection timing need to be adjusted manually, which requires relatively high proficiency of the machine operator.

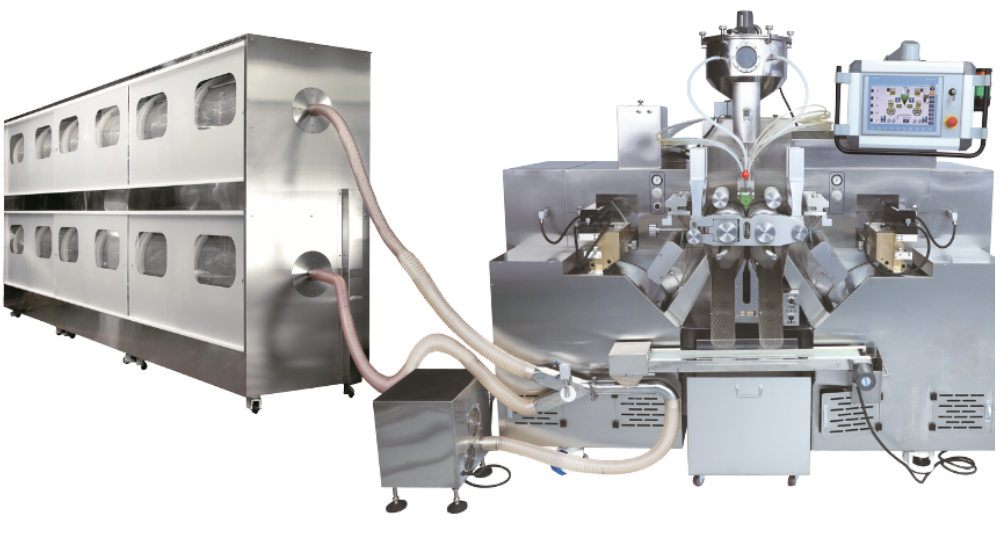

(Picture)

While the new technology soft gel capsule machine is with a servo driving system. The main parts of the machine are servo motor driven, which reduces the vibration caused by gear transmission, can increase the running speed of the soft gelatin machine, and improve the stability and output of the equipment. At the same time, the adjustment of die roller(tooling) alignment and medicine injection timing can be completed automatically by clicking the button on the PLC touch screen. Automatic alignment and automatic adjustment of filling volume adjustment are more friendly to operators who are new to soft capsule equipment and the operation is simpler and more convenient;

Besides, servo motor driving softgel machine is fully automatic system, with automatic gelatin film(ribbon) thickness adjusting system is installed, saving time and gelatin(starch)

- Make sure whether you only produce plant-based vegetarian gelatin softgel capsules or produce both animal gelatin soft capsules and vegan softgel capsules.

Basically, The softgel capsule machine that produces animal soft capsules and the soft gel capsule filling machine that produces vegetable soft capsules can be used universally. However, the temperature requirements of Vege-based starch gelatin are different from animal gelatin. This requires some modifications to the traditional machine for making animal soft capsules. Improvement to ensure better performance and encapsulation effect when the machine produces vegetarian source softgels.

- Differences Between Softgel Machines for Animal Gelatin Softgel and Tapioca Starch Veggie Softgel.

- Gelatin Spreader boxes:

For animal gelatin, open spreader boxes are OK, but since tapioca starch requires high temperature to melt when solidified, we make enclosed spreader boxes to prevent solidification.

- Die Roller Sets

For animal gelatin capsules, single step pocket design on die rollers are good. But since tapioca starch capsules are easier to leak, we need triple steps or bi-lips pocket design on die rollres to get stronger seaming.

During the encapsulation process of animal gelatin soft capsules, the gelatin ribbon needs to be heated by the spray segment(wedge) and then left and right rollers to make the gelatin film bond. The plant starch soft capsule gelatin ribbon needs maximum cooling during the encapsulation process, so the spray wedge does not need to be heated.

- Cooling Fans for Casting Drums

The temperature of the vegetable tapioca starch liquid is high, and the gelatin film needs to be cooled faster. Therefore, the tapioca starch soft gel capsule machine is equipped with a variable frequency and speed-adjustable cooling fan with a larger air volume in the machine frame box behind the casting drum. It replaces the small air volume fixed frequency fan originally installed under the casting drums of the animal gelatin softgel machine.

- Gelatin(starch) Liquid Transportation Pipline

For animal gelatin, food grade silicone hose is enough, but since tapioca starch liquid is with much higher temperature, silicone hose is easy to burst during encapsulation process, which is dangerous as well as timing consuming, we need to use stainless steel pipe instead.

- Piplines Inside Machines

During animal gelatin softgel capsule encapsulation process, we need to cool down the casting drum to cool the gelatin ribbon. But during tapioca starch softgel capsule encapsulation process, most of the time, the casting drums need to be cooled down while sometimes they need to be heated up, so the pipes we use inside the machine need to be stainless steel instead of traditional silicone hoses.

- Tapioca Starch Softgel Capsule Encapsulation Process

- Install and heat the gelatin transportation Pipes

- Requirements for gelatin delivery pipes: The temperature of starch gelatin is relatively high. It is recommended to use stainless steel pipes.

- The temperature of the gelatin liquid in the gelatin service tanks and gelatin delivery hose should always be maintained at 75℃. In order to achieve this temperature, we use electric heating tapes to tie the pipes to ensure that the temperature of the heating tapes is controlled between 75 and 85°C.

- Connect the gel pipe between gelatin service tank and gelatin spreader boxes on softgel capsule machine;continue to heat the pipe and maintain temperature at 75~85℃before the gelatin mass is transferred.

- Heat the gelatin spread boxes to 80℃. The required temperature of the gel mass inside the spreader boxes is 75℃. So the spreader boxes are to be heated to 80℃ before they are in use to contain gelatin liquid. Normally we heat them about 1 hour before they are in use.

- Temperature and humidity control in softgel encapsulation room. In the encapsulation room, the required temperature range is 20℃–26℃;The Relative Humidity (RH) shall be below 30%RH. The leaking risk of the softgelswill be increased when humidity is higher than 30%RH when they are rolling in tumble dryer. Please make such condition ready before encapsulation.

- Start to pressurize the starch liquid(gelatin mass) from gelatin service tank to gelatin spreader boxes.

- Start the soft gelatin machine and set the die roller rotating speed at 0.6~1.0 RPM. Start the casting drums and turn on the fans for the gelatin cooling drums and start to make gelatin ribbon.

- Measure the thickness of the ribbon and make it 0.6~0.8mm

- Start to encapsulate: Adjust the height of the die roller wedge to get them in touch with die rolls and gelatin ribbons, and then turn down the handle to inject the oil to test the loading capacity of the softgel shell. The process here is exactly same with that of animal gelatin softgels.

- Tapioca Starch Softgel Drying

- When coming down from softgel encapsulation machine, softgel capsules need to go into tumble dryers for shaping and initial drying. JANGLI developed a 3-layer tumble dryer with smaller but longer basket for tapioca starch softgel capsules drying! Because tapioca starch vegetable softgel capsules are fragile at the beginning, can not be squeezed or piled. With this 3-layer tumble dryer, capsules can keep rotating and transformed fast from one basket to the next, which can not only play a role in shaping, but also avoid the mutual extrusion between capsules and avoid leakage.

- After initial drying, the manufacturer can choose to move the capsules to drying trays for further drying or to use in-line tumble dryers to dry the capsules thoroughly.

- Or for the moment, we have intelligent tumble dryer for both animal softgel drying and veggie tapioca starch softgel drying, which is equipped with dehumidifier and air conditioner inside the equipment and humidity and temperature of each basket can be adjusted and controlled on PLC touch screen, no need to control room temperature and humidity.

- Conclusion

Plant soft capsules are becoming more and more popular and popular with the public. How to choose high-quality vegetable gelatin raw materials and equipment and services for encapsulating vegetable soft capsules and seize market opportunities are important issues for soft capsule manufacturers to study. JANGLI has more than 20 years of valuable experience in the soft capsule equipment industry. We can provide you with a comprehensive one-stop solution for the batch and high-quality production of vegan softgel capsule products, from the procurement and supply of plant collagen materials to the starch gelatin operating process. SOP, to the manufacturing and after-sales service of high-precision soft gelatin making equipment. Choose JANGLI and let us create greater value together!

Key words: Vege-based softgel/ vegetarian source softgel/ plant-based softgel/ Veggie softgel/ vegetarian softgel/ Vegan softgel/ vegan alternative softgel/ vegetable softgel