Most soft gel capsule manufacturers work hard to provide their customers with the best products. They want their customers to receive the capsules in the quantity and quality they desire. Soft gel encapsulation machinery is of the utmost importance in this case. Manufacturers seek equipment that will enable them to fulfill customer orders efficiently.

Even though most businesses may continue to use older, less modern models, updating is necessary. It is crucial to look for high-quality machinery because of the capital investment required for the equipment. But how can manufacturers determine which machine is best for encapsulating soft gel?

You will learn what a soft gel encapsulation machine is from this article. We detail the soft gel encapsulation machine’s operation, parts, and the industries it works best for. Finally, we discuss the benefits of selecting a soft gel encapsulation machine.

What Is Softgel Encapsulation Machine?

A device that aids in sealing soft gelatin capsules is known as a soft gel encapsulation machine. The machine ensures the correct quantity of gel is in the capsule. For example, picture how much work workers do manually to fill 500,000 soft gel capsules. The soft gel encapsulation machine, however, makes that process smoother.

Nutrient bioavailability can be delivered using soft gelatin capsules. The digesting process is made easier by small particle size. But how do manufacturers guarantee that quality standards are upheld even in these tiny sizes? By using suitable soft gel encapsulation machines.

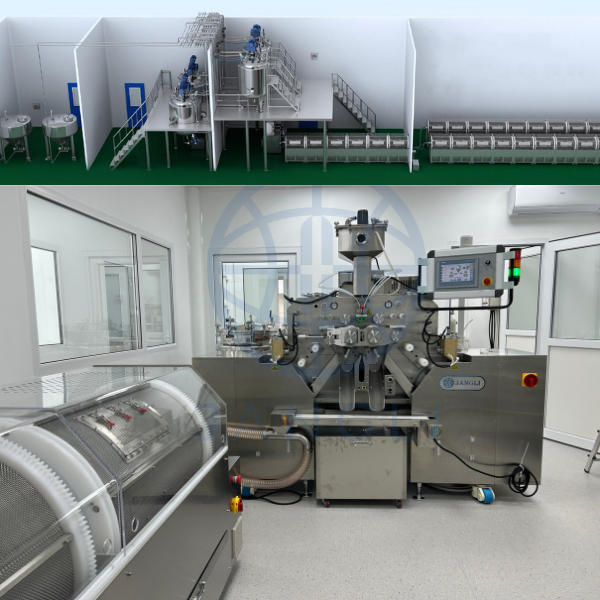

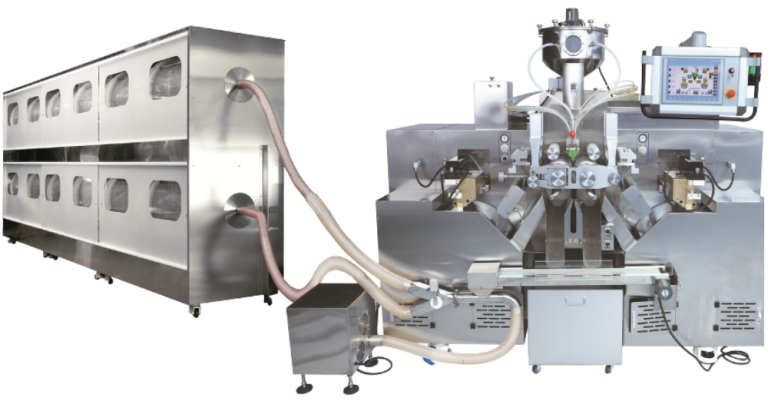

The soft gel encapsulation machine model can carry out several tasks. Soft gel encapsulation involves melting the gelatin, preparing the medicine, encasing them, drying, cleaning, and inspecting. You won’t need to buy several machines for the same task by selecting a suitable model.

What Are The Components of Softgel Encapsulation Machine and Function?

Depending on the type of soft gel capsule you plan to produce, you should buy a specific soft gel encapsulating machine. The quantity you wish to make is another factor you should consider. Check out the jl-150iii-soft-capsule-machine if you need a machine for medium-scale production and easy operation system with servo motor driving. We have numerous types of soft gel encapsulation machines.

The machines share some common parts, even if their uses are different:

We highlight the most common machine parts.

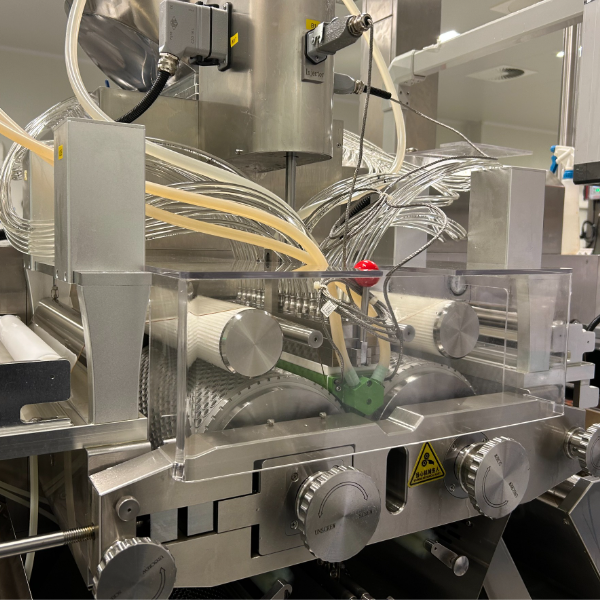

- Gelatin spreader box: Holds the melted gelatin, which leaves the melting and mixing tank. The spreader holds and spreads the gelatin into a thin film. Most soft gel encapsulation machines have two spreader boxes above the cooling drum.

- Product material tank: The tank is in the upper section of the machine. It holds the material you want to encapsulate.

- Injection wedge: It injects the fill material onto the gelatin film as it moves to the die chamber of the two rollers while heating the film to the proper temperature. Thanks to the pressure from the pump system, materials can flow through the injection wedge.

- Cooling drum: The gelatin ribbon solidifies as it cools. The cooling drum from the soft gel encapsulation machine has left the correct systems. The two rotate continuously in the direction the gelatin should flow. It can include a cooling fan and antifreezing solution to cool things down.

- Gelatine mixing/melting tank: The quantity of gelatin that needs mixing determines the size of this stainless steel tank. Along with the material, consider the melting tank’s operational temperature, power rating, size, and volume.

- Lubrication rollers: The rollers apply the lubrication solution on both sides of the web.

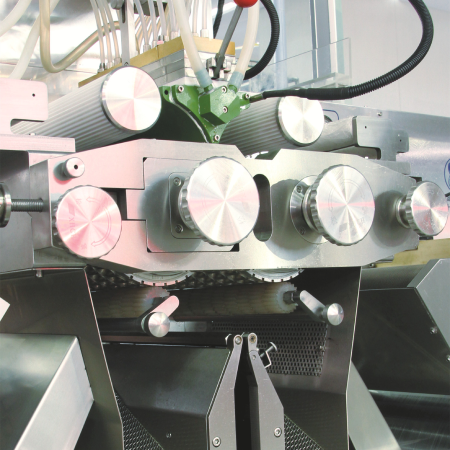

- Tooling system: Most soft gel encapsulation machines have two die rollers. The two rollers rotate, form soft gel capsules, and seal them after filling. Cavities on die rollers decide the shape and size of the final softgel capsules.

- Material feeding pump: It sucks material from the product material tank and directs it to the injection wedge. There are plungers(pistons) installed on the pump body to inject medicine. Please be aware that the accuracy of the soft gel encapsulation depends on the single plunger filling amount .

- Discharge chute: The chute transfers the hermetically sealed capsules to the conveyer belt for further drying, inspection, and sorting.

- Drying panels: The capsules from the conveyer are ready for drying. Their first stop is the tumble dryers and then the drying trays.

How Does Softgel Encapsulation Machine Work?

The working principle of the soft gel encapsulation machine is simple. Choosing a suitable soft gel encapsulation machine makes the process even more efficient.

Here is a simple process of how the soft gel encapsulation machine works:

- In the Gelatin Melting Tank, place the best gelatin formulation component.

- Mix and blend all the ingredients for the gelatine fill in the Medicine Preparation tank until a thick syrup forms. The syrup will then move to the cooler box, spreader box, and die rollers in that order.

- The next critical step is the fill material’s preparation. The fill material will be sucked from the medicine hopper and injected to the injection wedge system after you have made your soft gel capsule.

- The injection wedge system will bring together the fill and gelatin components. The gelatin substance is formed into the shape of the capsule using the two die rolls technique. The machine simultaneously injects the fill material into the produced capsule. The soft gel capsules then use the discharge chute for discharge.

- The soft gel capsules are moved to the tumble dryer via the conveyor in the discharge chute. Before transferring to the drying trays, the capsules will spend some time in the dryer.

Which Industry Can Use Softgel Encapsulation Machine?

Modern technology has allowed different soft gel encapsulation machine die rolls to be available. These die rolls determine the soft gel capsule’s size, shape, or design. Various industries have taken advantage of this and produced custom-designed products.

By 2032, the soft gel encapsulation machine market will likely increase by US$ 159.6 million. We list various industries and how they use soft gel encapsulation machines.

Veterinary industry

Animal medication administration can be challenging. Soft gel capsules make sure that animals get the correct dosage. Machines that can undertake this task are now readily available thanks to technological innovation.

Animals can receive nutrients thanks to soft gel encapsulation technology. The soft gel encapsulation machines make it easier and safe to administer nematicides and insecticides in capsule form.

Cosmetic/personal care industries

Ingredients in cosmetics typically need to be packed appropriately. The use of sticky silicone oil is growing in popularity. Additionally, most cosmetics are free of preservatives and water. Natural and organic personal care products also benefit from soft gel encapsulation.

Soft gel encapsulating machines aid in the packaging of cosmetic components. Manufacturers aim to create attractive products since the cosmetic industry thrives on appearance and quality. The soft gel encapsulation machine can use custom die rollers to create eye-catching shapes.

Soft gel encapsulation technology ensures that personal care products and cosmetics pass through machines with the highest hygienic standards. The machinery is practical and offers atmospheric stability.

Pharmaceutical industries

Soft gel encapsulation machines produce different pharmaceutical dosage forms. The gelatin capsule, one of the dosage forms, aids in the delivery of non-aqueous fluids. A suspended base or oil may be the active ingredient in the capsule. The soft gel capsule consists of an excipient in its inert form.

Soft gel capsules cover the harsh taste of the medicine—the pharmaceutical industry prefers it, especially for kids’ drugs. Additionally, soft gel encapsulation protects the drugs against contamination. The capsules are created by the companies using soft gel encapsulation equipment. The most popular soft gel capsules include Adalat, Zantac, Retinol, and Digoxin.

Food processing industries

The soft gel encapsulation market is also profiting from the food processing industry. Fish oils and nutritional supplements are now in capsule form. Most people can now consume dietary supplements and oils with an intense smell or taste thanks to soft encapsulation.

Paintball industries

The development of soft gel encapsulation has also reached the entertainment sector. Since the earliest days, paintballs have been a source of entertainment. The use of soft gel encapsulation machines significantly simplifies the procedure.

The machines will produce them in mass quantities and in various fun shapes. The quality and speed of the soft gel paintballs have replaced the earlier materials. The soft gel encapsulation machine can seal, dry out, and store after the paint fills the capsule.

Why Choose Softgel Encapsulation Machine?

While most people may choose dosator capsule filling machines, they may still need to get the desired results. The soft gel encapsulation machine saves you a lot of time and materials.

We highlight a few more reasons you should choose the soft gel encapsulation machine.

- It guarantees the stability of the soft gel’s active components, extending the shelf life of the capsule.

- Using the soft gel encapsulation machine, you can make soft gel capsules in any shape or size. You can do it thanks to the die cavity.

- You can create capsules that are simple to swallow.

- Your soft gel capsules will have hermetically sealed gelatin shells to protect them from moisture and air.

- When you want to produce soft gel capsules with the correct dosage, other machines will not give you the required accuracy.

- It’s easier to fill in the soft gel capsules with liquid or suspension with speed and efficiency.

Frequently Asked Questions

- What are the different types of capsules?

There are two basic types of gels: soft and hard gels.

- Soft gels provide a high content consistency and are easy to swallow. Their components include gelatin, water, coloring, plasticizing agents, and other excipients. The gelatin in a single piece makes up soft gel capsules. Since water dissolves gelatin, most soft gel capsule solutions are oil-based.

Soft gels are more flexible and take longer to break down in the body and release their contents. They are often produced using just one machine and are available in various shapes and sizes.

- Hard gels consist of a cap and a capsule, with the cap being the smaller of the two. Colorants, plasticizers, gelatin, and opacifiers are their key components. The chemicals in the capsules are solid.

The drug releases from hard gel capsules after three minutes of fast dissolving. Only a standard cylindrical shape is available; therefore, you’ll need two machines. One is used to make the shells, while the other fills the materials.

- What are the recommended quality standards for a soft gel encapsulation machine?

You must ensure the soft gel encapsulation machine you buy passes the recommended quality standard inspections. The checks tell you that the soft gel encapsulation machine you want to buy has passed all the tests related to processing products.

You’ll first need to confirm that the soft gel encapsulation machine has received approval for cGMP (current good manufacturing practices). The rule ensures that the soft gel encapsulating machine maintains precise testing standards and appropriate operational procedures and uses quality materials.

Another requirement for your machine is that it must meet Food and Drug Administration (FDA) standards. You produce a large majority of goods meant for human or animal use. FDA controls the handling of food and dietary supplements to safeguard public health.

Ensure that your device has the CE Marking. It is an essential requirement for manufacturing plants’ quality standards. CE Marking is a manufacturer’s declaration that their products meet EU standards for protecting human health and the environment.

The final quality standard requirement is the International Standards Organization (ISO) standards. These are standards that experts have agreed upon globally to dictate quality management and assurance by companies.

Conclusion

Whether you need to produce small, medium, or large quantities of your products, soft gel encapsulating machines guarantee that you can seal them fast and effectively. The machines come in a variety of designs. Before deciding, you must choose what soft gel products you want to manufacture and how many. Soft gel encapsulating machines have several parts and are easy to work with.

You want to be sure you are making the best investment possible before spending significant money on a soft gel encapsulation machine. When you approach us, our team at Jangli Equipment will help you analyze what will work for you and help with the installation. We continue offering our support way after.