As the largest softgel die roller manufacturer in China, JANGLI provides various size and shape die roller sets for all around the world and has a lot of designing, using and maintaining experiences.

During softgel production process, die rollers are very important toolings, which determine the shape and size of soft capsules. And die roller quality affects the capsule quality directly. However, softgel die rollers are easy to damage, softgel manufacturers have to be very careful to handle them. Here are some occasions the die roller keepers need to check and inspect the die rollers carefully:

- When new die rollers first arrive to factory

- When someone bumps the die rollers accidentally

- When there are foreign objects falling on die rollers during encapsulation process

- When individual capsule leaks

Die roller is cylindrical and the inspector needs to roll it slowly manually, which is not a problem for small softgel machine toolings. But for bigger soft gelatin machines, die roller will be very heavy and not easy to hold and check manually. And the inspector can only put the die roller on a platform or desk and move and check slowly.

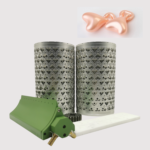

In response to this situation, JANGLI designed a small tool specifically for the inspection of soft capsule molds. This mold inspection tool consists of three parts: a bracket, a mold fixing plate and a rotating handle. Gently fix the mold to the die roller holder, then insert the handle from both ends and place it on the bracket. You can turn the softgel machine mold at will with one hand, freeing your hands to use tools to inspect the mold.