What Is “Jumbo” Softgel Capsule Machine?

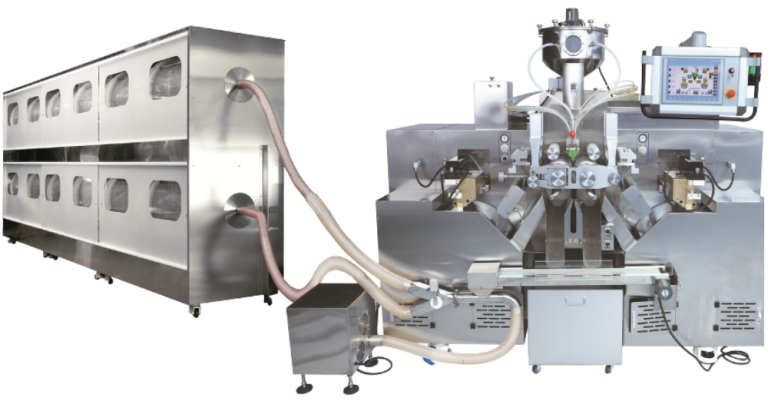

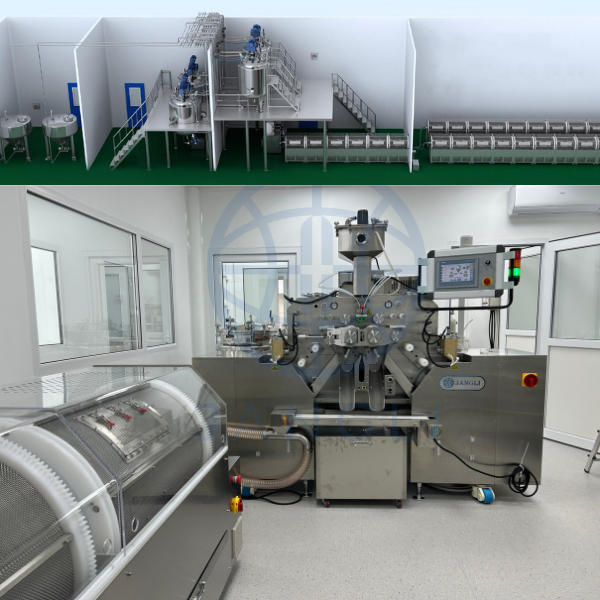

Softgel Die Roller dimension decides the size of softgel encapsulation machine. The bigger the die roller is the larger the softgel capsule machine is. For the moment, there exists 4’’ 6’’ 7’’ 8’’ 10’’ and 12’’ size softgel machines. And 12’’(die roller size: diameter 200x300mm) is the biggest size for the moment, which is the “jumbo” softgel capsule machine; JANGLI JL-300 Softgel Capsule Machine is a Jumbo machine. It is the biggest softgel machine we have for the moment.

What is the advantages and disadvantages of the Jumbo softgel capsule machine?

Advantages:

- Bigger size die roller means more cavities and larger production capacity;

Disadvantages:

- Bigger size die roller and bigger machine means more weight on the die roller and machines, which will generate more vibration, which will affect the precision of the softgel machine and the seam rate of soft capsules.

- Every time before production, the operator needs to install the softgel die roller set onto the encapsulation machine and demount it after production. And when die roller size is big, the die roller set is super heavy, which makes the operation more difficult and easy to damage the die roller set.

What is the features of our JANGLI “Jumbo” Softgel Capsule Machine?

- Servo Motor Driving System:

For this Jumbo 12 inch 300 softgel capsule machine, we supply only with servo motor driving system and never common gear driving system. With servo motor driving, the main axis and other main parts of the machine are driven by separated servo motor, which will reduce the vibration caused by gear driving;

By using servo motor system, all the die roller alignment and timing and filling volume adjusting jobs can be completed on the PLC touch screen, which can reduce the operation difficulty and save time and reduce gelatin waste.

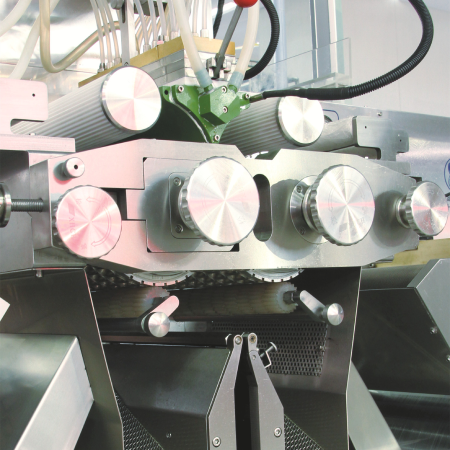

- High Quality and High Precision of the Main Axis:

Main moving parts are used accurated Germany bearings and P4 high accuracy bearings

The parallelism of two axis is less than 0.02mm and the round jump of the softgel die roller is less than 0.02mm

- Round and Fine Treatment Material Hopper :

Round hopper can reduce filling material waste and easy to clean.

Our Softgel capsule machine hopper are welded well and All stainless steel Solder joints are light treated, beautiful appearance.

There are sealing gasket and closing handle installed on the hopper and the hopper can be sealed and fill nitrogen when needed.

The hopper is designed double layers and there is a heating layer with water inside and can be heated when needed.

- Automatic Gelatin Thickness Adjusting System(ATGS):

With the ATGS system installed on our softgel capsule machine, the operator just need to input the target thickness of the gelatin film and the ATGS system can detect the thickness and adjust automatically, which reduce gelatin waste by adjusting manually.

- Use water cooling system instead of air cooling system.

Grow Your Business With Jangli

Contact us for more details

CONTACT US