Introduction

Many people around the world invest heavily to take care of their health. One of the main ways to do this is by taking supplements. Nowadays, these helpful vitamins are administered through a special medium known as soft gelatin capsules. They are convenient, hermetically sealed and can be consumed without water! A big advantage of softgel capsules is that they can contain liquids, semi-liquids or suspensions. To produce high-quality softgels, it is necessary to use a capable machine such as those provided by Wuxi Jangli Machinery Co. Ltd. Here is more on this company, and their world-renown softgel encapsulation machines.

Who are Wuxi Jangli Machinery Co. Ltd?

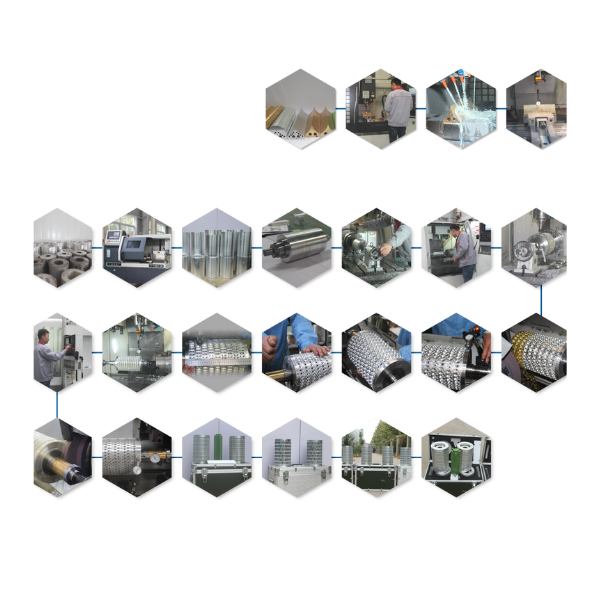

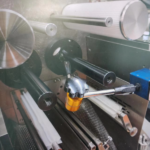

The Wuxi Jangli Machinery Company has produced softgel encapsulation machines for more than twenty years. They use advanced technology to produce high-quality products. the company has built a 6,000m2, 6 Sigma workshop, over the time that they have been operational. Inside, there are more than 20 CNC processing stations for the production of precision parts such as die rollers. The company has an army of more than 300 technicians, engineers, and subordinate staff to set up, configure, and monitor the CNC stations.

Clearly, Wuxi Jangli Machinery Co. Ltd have invested heavily in production capacity. Therefore, they are able to sell more than 100 softgel machines all over the world annually. They also sell more than 1,000 softgel die roller sets for various brands of machines. Along with this, the company sells more than 300 tumble dryer baskets designed for use in standard or intelligent tumble dryers.

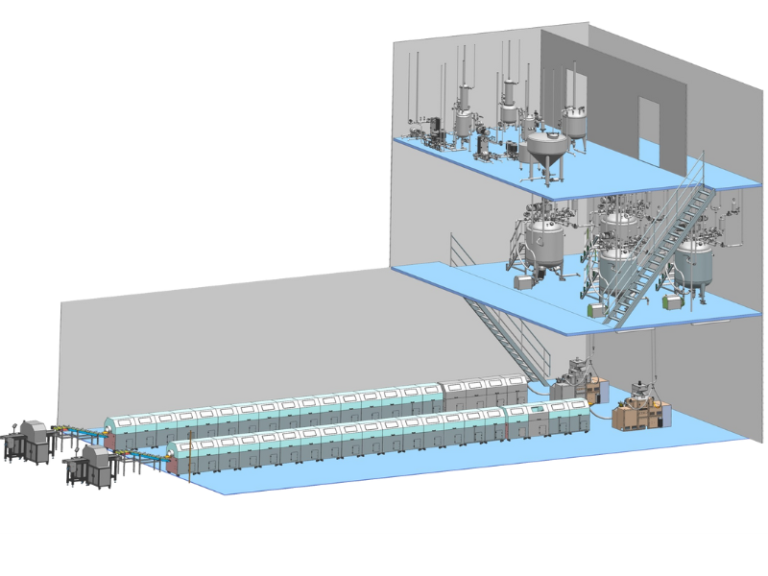

At the Wuxi Jangli Machinery Company, they strive to help customers attain maximum value. As such, they also produce a variety of complementary equipment to assist clients in building their softgel encapsulation production lines. As such, the company also sells more than 50 lines of softgel machine accessories such as medicine tanks, gelatin melters, and gelatin service tanks. Their high rate of production makes them one of the top softgel encapsulation machine manufacturers today!

Quality Control at The Wuxi Jangli Machinery Company

Every soft gelatin encapsulation machine that leaves the factory has attained a substantial level of quality. Here is how the company ensures maximum functionality, and reliability in their products:

Design Lead Quality

There are more than 20 designers who create professional designs, and protocols for each client.

Raw Material Control

The raw materials that are used in manufacturing softgel encapsulation machines must be of high quality. Therefore, the technicians employ several instruments to confirm the suitability of the raw materials. Moreover, the raw materials are only utilized after passing the checks and receiving an official certificate.

Efficient Production Management

There are advanced CNC stations in the workshop that are managed by skilled technicians. These stations utilize the latest technologies to ensure maximum output.

Comprehensive Testing Procedures

The company engages in active testing of various elements in the production of softgel encapsulation machines. They perform injection accuracy, and software system testing. Furthermore, the technicians conduct extensive testing on the melter. Here, they test it for vacuum, pressure, heating capability and surface roughness.

By performing these quality control tests, the Wuxi Jangli Machinery Company ensures customer satisfaction with their products.

Machines Available For You at Wuxi Jangli Machinery Co. Ltd

There are numerous machines to select from at the Wuxi Jangli Machinery Company . One of their premiere models is the R&D Veggie softgel making machine. It is developed for use in laboratories and to create pilot batches for startups. By using this machine, you can reduce the amount of wasted material during your Research and Development (R&D) efforts. Here is more about this compact machine.

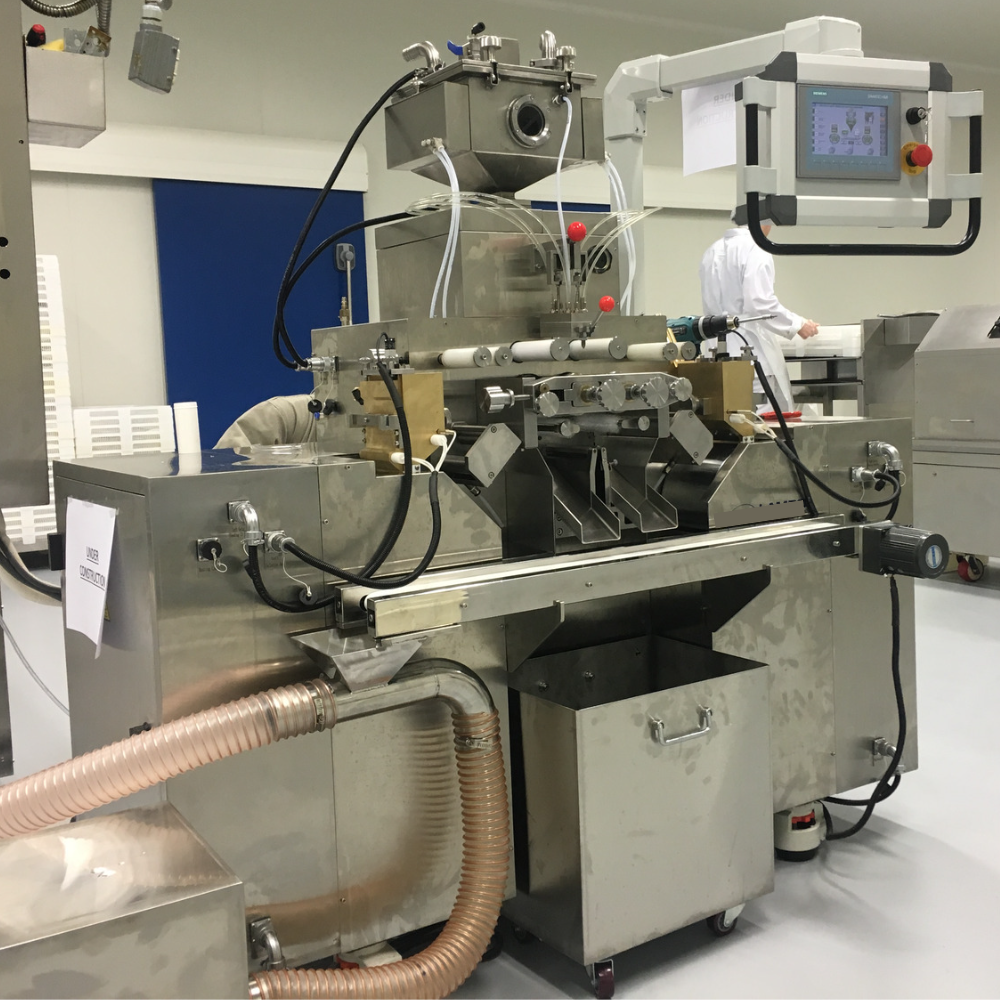

The R&D Veggie Softgel Making Machine

Vegetable based supplements have gained popularity in recent years. Therefore, the nutraceutical industry has grown into a bustling sector for entrepreneurs. The R&D Veggie softgel making machine is ideal for startups because of its unique design. This softgel filling machine is inexpensive to run, has a small shape, and is easy to adapt. Here are more features of this machine:

SIEMENS PLC Control Panel: This softgel encapsulation machine can be manipulated through a touch sensitive control panel. The SIEMENS PLC screen has a color interface and is intuitive to use.

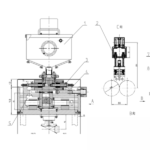

Minimalist Die Roller: The machine has a minimalist die roller that is compatible with the small sizes of the capsules that it makes. The die roller has a diameter of 80mm and a length of 100mm.

Portable Medicine Injection Pump: To maintain the compact proportions of the R&D Veggie softgel making machine, it has a small medicine injection pump. This pump has only 6 plungers, with 3 positioned on each side.

Robust Construction: All the panels on this soft gelatin machine are made of SUS 316L stainless steel. As such, the machine is light and strong at the same time.

Low Power Consumption: Even when running at full capacity, this machine consumes only 5kW. As such, it is very economical to operate.

There are some unique parts of this machine that have been enhanced to ensure peak performance. They include:

A Stronger Blowing Fan: Regular softgel making machines have a blowing fan rated at 280W. However, the R&D Veggie softgel making machine contains a blowing fan rated at 400W. Seeing as starch (plant-based) gelatin requires a very high temperature, it became necessary to have a bigger fan for faster cooling of the ribbon (gelatin film).

VFD-Controlled Tumble Dryers: This softgel encapsulation machine has a tumble dryer whose speed can be controlled steplessly. This is opposed to traditional animal gelatin softgel machines that have a fixed rotating speed. The R&D Veggie softgel making machine uses delicate, plant-based gelatin. Therefore, the tumble dryer speed needs to be slow at first and then gradually increased.

New Pipes: All the pipes in the softgel-making machine are now made of stainless steel because vegetable softgel sometimes requires high temperature of up to 99°C.

Conveyor Belt: The finished capsules are transported to the collection chute through a conveyor belt instead of a blower. As a result, the capsules will not break open.

Due to these characteristics, the R&D Veggie softgel making machine is perfect for application in a R&D capacity, education or in a startup company.

Conclusion

Manufacture high quality vegetable softgel capsules using the R&D Veggie softgel making machine. Made by the Wuxi Jangli Machinery Company, it combines compact dimensions with high effectiveness. Featuring new technologies such as stainless steel pipes and a strong blowing fan, this softgel encapsulator is your best bet. Buy it now at a pocket-friendly softgel encapsulation machine price from Wuxi Jangli Machinery Co. Ltd and grow your startup in leaps and bounds!

Grow Your Business With Jangli

Contact us for more details

CONTACT US