At present, as the world’s population is getting smaller and smaller, labor is getting more and more expensive, and the degree of automation is getting higher and higher, how to save labor to the maximum extent to save production costs has become an issue that manufacturers are paying more and more attention to, and the same is true for the softgel production industry, especially in North American countries such as the United States and Canada, where labor is very expensive. Fully automatic soft capsule production equipment and more efficient soft capsule drying methods are now highly respected. As a professional softgel equipment supplier, JANGLI has been paying attention to this issue and constantly researching ways to save labor in the softgel capsule production process. Currently, we have made the following improvements. The entire soft gelatin capsule production line only requires 5 people to complete efficient production.

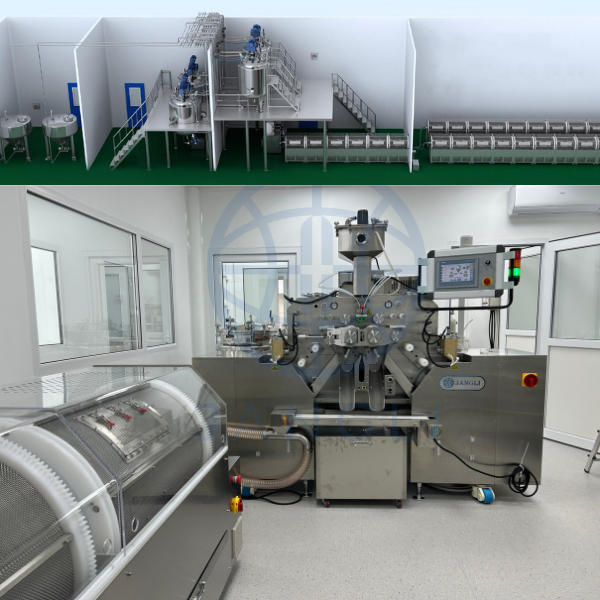

- Gelatin Melting Process:

Use our Fully automatic gelatin melting system, and the whole gelatin melting process requires only 1 worker.

Compared with traditional gelatin melting system–the worker has to manually load gelatin and water and other materials, manually start the gel tank heating and stirring, remember the heating time, manually start vacuuming, and manually discharge gelatin solution when it is ready, our digital intelligent gelatin melting system can complete the whole melting process like gelatin and water input, heating, stirring, liquid gelatin vacuumizing and bubble removing automatically. And this system can automatically control the gelatin solution temperature and positive and negative pressure according to the actual production process. It can suck the material into the gelatin melting tank and weigh it, and accurately calculate the weight of the material. It can not only reduce the error of the formula and the process of weighing outside the tank, but also avoid eliminates cross-contamination and reduces reliance on workers’ experience and proficiency, eliminating manual inspection and intervention.

During the gelatin melting process, the worker just need to input all the parameters on the PLC touch screen and the whole melting process can be completed automatically and precisely.

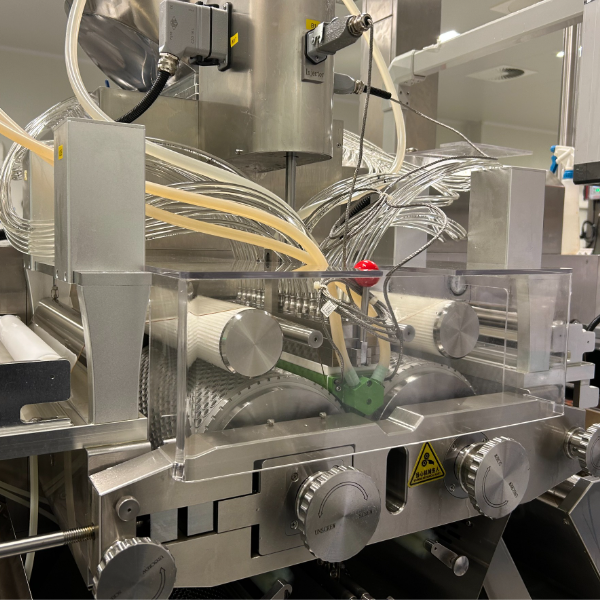

- Softgel Encapsulation Process:

For larger scale softgel production manufacturers, we recommend our SERVO softgel encapsulation machines, and only 1 operator is needed to operate the machine.

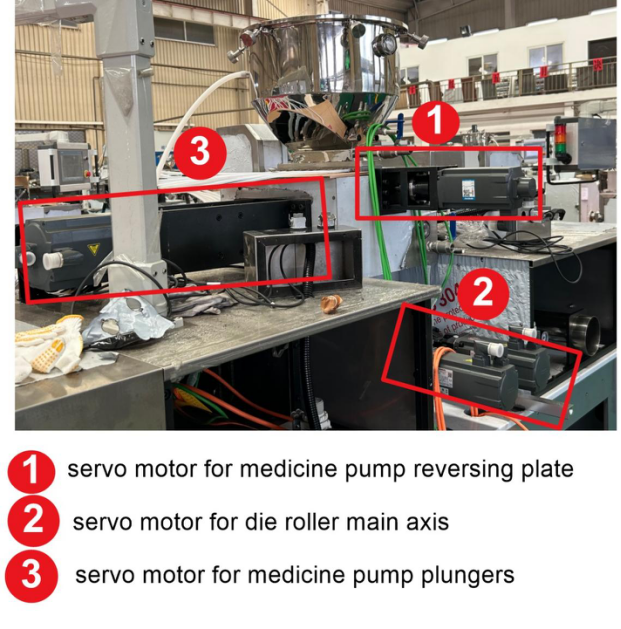

JANGLI’s servo soft gelatin making machine adopt servo motors fall all the critical parts on the machine–servo motor directly driving die roller main axis, servo motor directly driving the medicine pump plungers and servo motor directly driving the medicine pump reversing plate. And this means softgel die roller alignment and softgel filling volume and injection timing can all be finished automatically.

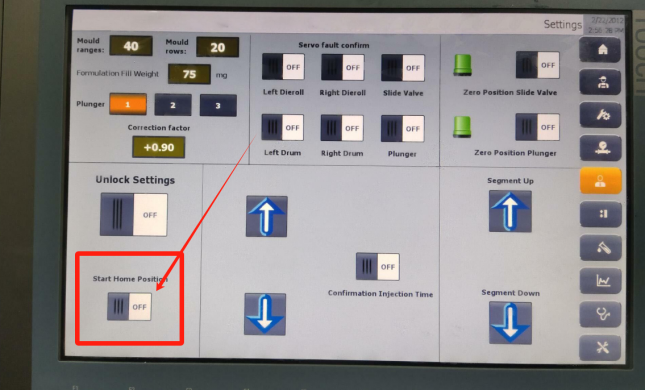

- As you may know, when start running a traditional gear driving softgel encapsulation machine, 2 operators needed to do the die roller alignment, 1 is in the back side to move the gear and 1 is in the front side to watch the die roller position and the whole process takes a lot of time, and it’s not very easy for a new operator to learn. By using JANGLI’s servo gelatin encapsulator, the operator just need to click the “alignment” button and the machine will finish alignment process all by itself and very fast, which saves a lot of time.

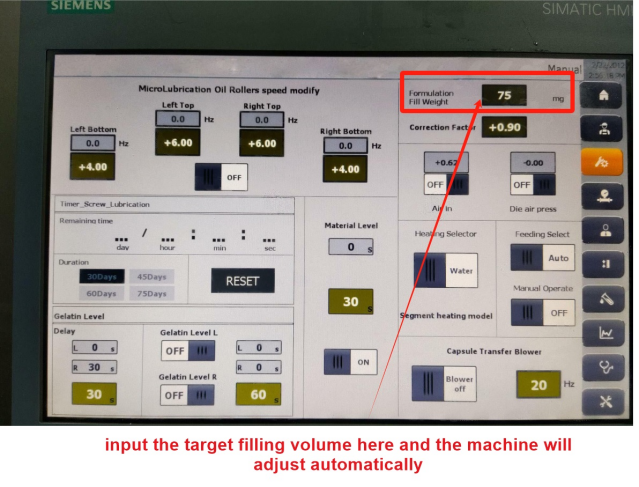

- For traditional gear driving machine, the filling volume of the soft capsules is adjusted manually, which also need at least 2 operators, and 1 operator need to rotate the adjusting knob manually slowly and the other operator need to weigh the capsule, and they need to keep doing this until the filling volume is correct. This cost too much time and waste a lot of raw material.

By using JANGLI’s servo soft gelatin machine, servo motor makes it much easier to adjust the filling volume and just input the target volume on PLC touch screen and it can adjust automatically.

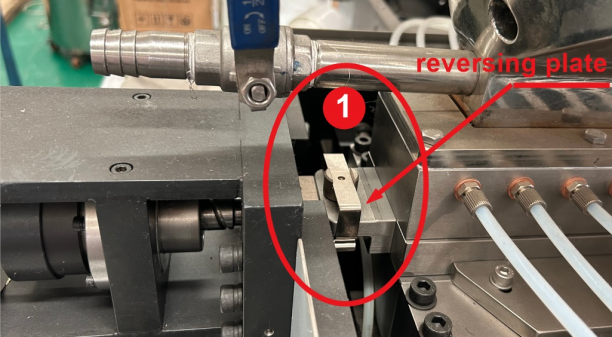

- The last one is the servo motor for the reversing plate, this is JANGLI’s unique design–servo motor for the medicine reversing pump. Servo motor direct driving to replace the traditional gear driven cam makes the softgel machine runs more stable, so that the rotating speed of the machine can be faster.

To sum up, 1 operator to operate JANGLI’s servo motor softgel making machine is enough and the operator just need to check the machine in every 20 minutes, and from starting the machine to normal production, 5 to 10 minutes is enough, which saves labor, time and raw material dramatically.

To learn more features of JANGLI’s servo soft gelatin encapsulation machine, please refer to this article:

Main Features JL-250III Servo Softgel Machine Detailed Introduction

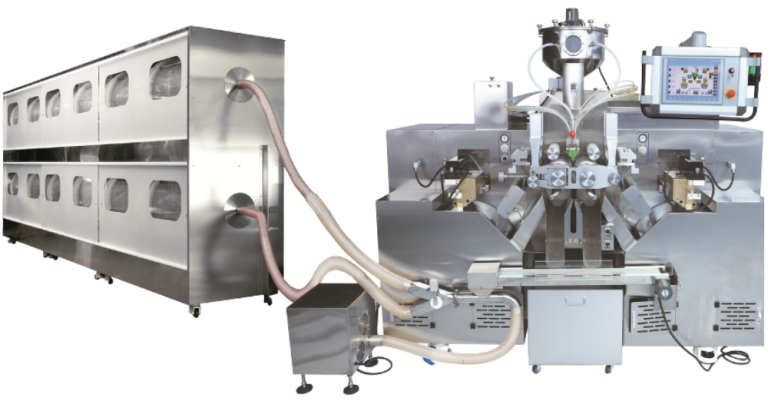

- Softgel Drying Process:

- We recommend our intelligent dehumidification tumble dryer for large softgel production. And only 1 worker is needed for softgel drying.

- As you know, softgel drying is a very important link during the whole softgel production process, and it always takes a lot of space or a lot of labor. The most traditional softgel drying method is tray drying, which requires a very low temperature and humidity inside the drying room–drying room temperature 20C and humidity 18% and at the same time, the workers need to flip the soft capsules tray by tray very often, which cost a lot of energy and labor.

- Another more labor saved softgel drying method is in-line tumble dryer drying, which uses no softgel drying trays but use standard tumble dryers for the whole softgel drying process. Compared with tray drying, in-line tumble dryer needs less labor, but much more spaces to achieve good drying effect. For example, a 10’’ softgel machine 24 hours production needs at least 36 baskets of tumble dryer to guarantee non-stop production and through drying, which requires a lot of space for drying room.

- To solve these existing problems, JANGLI developed Intelligent dehumidification softgel tumble dryers in 2019 and this new style of softgel drying method is becoming more and more popular these years. This tumble dryer is closed structure with built-in dehumidifier and water cooling unit and no need to control the whole drying room temperature and humidity, it control the temperature and humidity inside the tumble dryer drying basket directly and so that the room needed to be control the temperature and humidity is much more smaller and we can concentrate all energy to control a smaller space. And thus we can realize very good drying effect in a shorter time and at the same time a 10’’ softgel machine 24 hours production needs only 24 basket of dryer for non-stop softgel production.

Dehumidification automatic intelligent softgel drying tumble dryer-built-in dehumidifier

- Softgel Inspection Process:

- Softgel inspection and sorting process is a very time-consuming and labor-intensive process during softgel production process, because it requires manual use of eyes and hands to remove unqualified softgel capsules and then pack the qualified capsules. Some semi-automatic softgel capsule picking machines can sort capsules of qualified sizes. It saves some manpower but is not very helpful, because in addition to size, soft capsule sorting also needs to identify whether there are surface defects such as black spots, which are still needed completed manually.

- To solve this pain point, JANGLI developed this Fully automatic softgel inspection and sorting machine, and this machine need only 1 operator. This automatic softgel sorting machine is equipped with the most advanced visual processing system and driven by servo motors and 4 cameras installed above the photographing area to guarantee the detection accuracy. All the one operator need to do is to put the dried up softgel capsules into the capsule store tank and this automatic softgel picking machine starts to work automatically, and it will detect and reject break capsules, shaped capsules, spotted capsules, out-of-size capsules and bubble capsules fast and accurately and then transport the qualified softgel into the boxes.

- And we can also designed a softgel vacuum conveying device, which will transport the softgel capsules from the tumble dryer directly to the automatic softgel capsule sorting machine, which is more convenient.

To sum up, according to JANGLI’s above plan, during the whole softgel capsule production process, you only need 1 worker for the gelatin melting process, 1 working for the softgel machine encapsulation process, 1 worker for the softgel drying process and 1 worker for the softgel inspection and sorting process, and 1 spare work, so totally 5 workers needed only.

If your soft capsule production company urgently needs to solve labor problems, come to JANGLI. We will customize a complete and intelligent solution that is most suitable for your situation and save you labor to the maximum extent.