The nutraceuticals, food, cosmetic, and pharmaceutical industries use soft gel encapsulation machines. The machines are available in various capacities to meet the production requirements of each sector. When selecting a soft gel encapsulation machine, consider your production budget, volume, and industry needs.

Gelatin capsules are filled with liquid or semi-liquid ingredients using a soft gel encapsulation machine. The substances are protected from outside effects by the airtight shells. You should use soft gel encapsulation machines to ensure homogeneous ingredient combinations. How many capsules you can produce depends on the machine’s capacity.

In this comprehensive article, I describe a few soft gel encapsulation machine types by capacity and the factors determining the machine’s capacity. To meet your production needs, I will give you a few tips on picking the best soft gel encapsulating machine.

Types of Soft Gel Encapsulation Machines by Capacity

Regarding soft gel encapsulation machines, “capacity” refers to the production volume or the number of capsules the machine can produce in a given time (measured in capsules per hour). Knowing a machine’s capacity will help determine whether it is the best option for your production requirements.

Unlike other machines like the hard shell capsule machine, most soft gel encapsulation machines are entirely automated. I examine the various soft gel encapsulating machine types based on their capacity.

High-speed soft gel machines

The machines are popular in large-scale manufacturing facilities that need a lot of soft gel capsules. Large pharmaceutical or nutraceutical companies with significant production demands use the machines. You can effortlessly produce huge amounts of soft gel capsules because of high-speed soft gel machines’ remarkable production capacity, speed, and efficiency.

Up to or more than 200,000 capsules can be produced per hour by high-speed soft gel machines. You can better meet the needs of large-scale activities if your manufacturing capacity is higher. The machines’ numerous customization options allow them to accommodate different capsule sizes and formulations. They feature interchangeable tooling options, such as

- Tamping pins.

- Pumps.

- Die rolls.

Because of its versatility, you can make various soft gel products using the same machine.

The machines’ advanced control and monitoring automation features optimize the filling, sealing, and drying operations. These technological advances allow operators to closely monitor crucial process variables, including humidity, temperatures, and drying times. With real-time monitoring, you can maintain consistent capsule quality with precise control while lowering the likelihood of defects and unwanted variations.

Most high-speed soft gel machines use a rotary-die configuration. The soft gel dies roller set has multiple die rolls, which enhances production speed. Production can be done effectively and continuously thanks to the setup, which boosts overall capacity.

The high-speed soft gel machines are built with high-quality materials and precision engineering to withstand rigorous production demands. They undergo thorough quality control procedures to minimize downtime and assure long-term performance, durability, and accuracy.

High-speed soft gel machines can handle your huge production volumes and market demands if you are a big firm.

Medium-scale soft gel machines

These machines are made to handle medium-sized production quantities. They are used primarily by contract manufacturers or small to medium-sized manufacturing businesses. The machines are appropriate for organizations that need a moderate output of soft gel capsules because they balance production capacity, adaptability, and cost-effectiveness.

The machines can produce 50,000 to 100,000 capsules each hour, sufficient to suit the needs of mid-sized manufacturing firms. They can handle different-sized capsules. The machines have tools that can be easily customized for different soft gel formulations, including interchangeable die rolls.

Medium-scale soft gel machines include advanced automation capabilities to guarantee precise and dependable capsule filling. Additionally, they contribute to reducing human errors and improving overall manufacturing efficiency. The advanced features include

- Precise dosing mechanisms.

- It has sophisticated control systems.

- Automatic feeding systems.

The machines provide a cost-effective alternative to increasing production volumes without investing in larger, higher-speed equipment. They offer a balance between investment cost and production capacity.

Operators can successfully handle the encapsulation process using medium-sized soft gel machines since they are easy to use. They are easy to maintain and clean, reducing downtime and increasing production output.

Lab-scale soft gel machines

The machines are primarily made for small-scale production, usually in pilot or research factories. They are appropriate for making small batches of soft gel capsules for testing, market sampling, and formulation research because they have a reduced production capacity.

Compared to medium-scale and large-scale machines, lab-scale soft gel machines are small and take up less room. They can produce between 5,000 and 25,000 soft gel capsules an hour. Their small size allows for easier installation and mobility, and you can easily move them.

The machines often have replaceable die rolls and other parts, making switching between capsule sizes or compositions simple and rapid. They can accommodate various capsule sizes, from smaller sizes 8 to 10 to bigger sizes 20 to 24.

Lab-scale soft gel machines provide user-friendly controls and simpler processes. For those who need a more soft gel encapsulation experience, they are simpler to use thanks to their user-friendly software and straightforward interfaces. The machines’ minimal maintenance needs make cleaning up after them simple.

In terms of initial investment, lab-scale soft gel machines are more cost-effective. Their smaller production capacity aids in reducing operational costs such as labor, utilities, and raw material usage. As a result, they are a good option for startups, small businesses, and laboratories with tight budgets.

Customized soft gel machines

Customized soft gel encapsulation machines are also offered in the market in addition to the three types of equipment previously described. They are customized to fulfill certain manufacturing needs, accommodating extra capacities or features per your requirements.

Most businesses would use specialized soft gel encapsulation equipment when they require specialized soft gel capsules. Customized soft gel machines provide flexible options for production capacity, capsule sizes, features, and formulations.

I point out a few crucial qualities and traits of customized soft gel machines:

- They can handle a variety of capsule sizes and shapes. The shapes can be small, standard, or large with unique shapes (oblong, oval, or custom-designed).

- Customized soft gel machines allow for a wide range of capsule formulations. They can process oil-, water-, or suspension-based formulations. The machine has specialized pumps, heating, and mixing systems to encapsulate various formulations effectively.

- The machines are equipped with additional features or integrated with other machinery to increase productivity. Among the features are automatic feeding systems, quality control inspection systems, and enhanced drying capabilities. You can request any of these features from the machine’s manufacturer.

- The handling of delicate or sensitive substances needing special handling or processing conditions is accommodated by customized soft gel machines. Additionally, they can be modified to work with specific soft gel capsules, including time-release or centric-coated capsules.

- The machines are made to adhere to the industry’s specific quality and regulatory criteria. It calls for adherence to cGMP (current Good Manufacturing Practises) standards and compliance with legal and regulatory regulations, such as those set down by the FDA for pharmaceutical products or ISO standards for quality assurance.

You must collaborate closely with the machine manufacturer and communicate the specific requirements and expectations. Only then will the manufacturer design and build the machine to meet your needs.

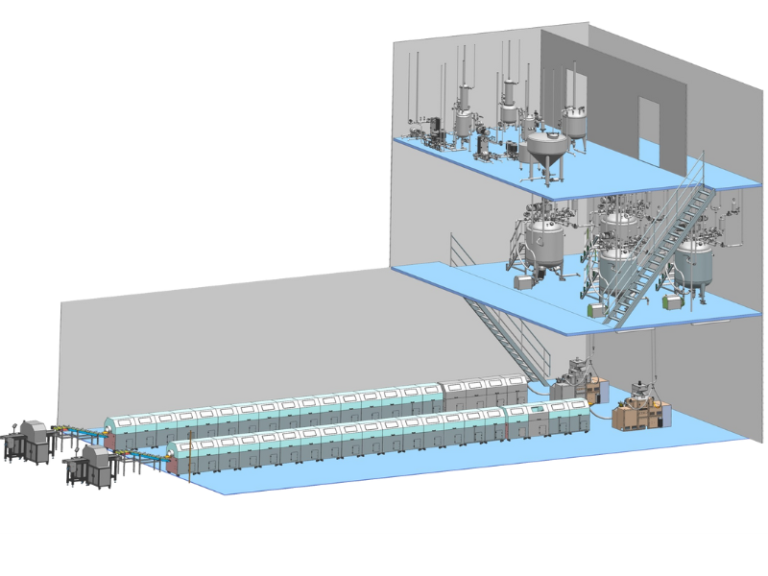

Read more on how to equip your soft gel production line for success.

Which Factors Affect Soft Gel Encapsulation Machine Capacity?

The following factors influence the capacity of a soft gel encapsulation machine:

- Automation level: The degree of automation impacts a soft gel encapsulation machine’s production capacity. The production rates can be increased by fully automated soft gel machines constantly operating without operator involvement. These machines can work at larger degrees thanks to their advanced capabilities, which include automatic feeding systems, effective cleaning mechanisms, and precision control.

Some parts of the production process for semi-automatic soft gel machines will need human help. After entering the required requirements, you must closely monitor the production process. Conveyor belts are rarely used in semi-automatic soft gel plants to transport the products. Some cleaning processes will also require human assistance.

- Machine design and size: The capacity of the soft gel encapsulation machine is also influenced by its size and design. The number of die rolls used by various machines to shape soft gel capsules varies. Machines with multiple die rolls produce more capsules each production cycle, increasing their overall capacity.

- Operator experience and training: The real production capacity is influenced by the knowledge and expertise of the machine operators in your company. Your machine operators will be better able to solve problems, know how to maintain the machines, and will be more likely to reach higher production rates if they have received proper training.

- Configuration: Your machine is set up as a single station. Single-station machines have a lesser capacity and operate more slowly. You can also set up your equipment as rotary die machines with a higher capacity and make many capsules simultaneously.

- Overall efficiency: More capsules can be produced by machines with increased efficiency over time, increasing their capacity. Machines with less downtime for maintenance and cleaning can also increase capacity and maximize production time.

Please be aware that a soft gel encapsulation machine’s stated capacity is an estimate given by the manufacturer. The capacity you can produce will differ depending on capsule size, machine configuration, environmental circumstances, and encapsulation formulation.

How to Choose the Right Soft Gel Encapsulation Machines

The effectiveness, output, and quality of your soft gel encapsulation process might be affected by the type of soft gel encapsulation machine you select. Consider the following factors so that you can make an informed decision:

| Factors to consider | Characteristics |

| Production requirements | -Potential production and desired output. |

| -Determine how many soft gel capsules you want to manufacture each hour or each day. | |

| -Aids you in choosing the right machine size and output capability. | |

| Budget considerations | –How much will you spend on the soft gel encapsulation device? |

| -Take into consideration the initial costs. | |

| -How much will it cost to run the business in the long term in terms of labor, raw materials, and utilities? | |

| -compare the costs of various machines, their features, capacities, and the value they offer for your particular production demands. | |

| Machine reliability and durability | -Search for equipment with premium components and precision engineering for long-lasting performance. |

| -Machinery with dependable parts are more likely to function consistently and endure the pressures of continuous manufacturing. | |

| Capsule sizes and formulations | -Consider the range of capsule formulas and sizes you intend to produce. |

| -Ensure the selected equipment can process the precise capsule sizes and formulations you need. | |

| -Choose machines with interchangeable tooling that are flexible enough to handle a range of capsule sizes and formulations. | |

| Machine features and automation | -What features and automation abilities do the machines you’re evaluating have? |

| -Seek out advanced automation features like precise dosing mechanisms and automatic feeding systems. | |

| Maintenance and support | -Assess the machine’s maintenance needs and the support that the manufacturer offers. |

| -The ease of cleaning, the accessibility of spare parts, technical assistance, and maintenance practices are all important considerations. | |

| -Simple maintenance methods and dependable assistance for the machine guarantee continuous operation. | |

| Reputation and reviews | -Research and evaluate the machine operator’s reputation. |

| -Read customer reviews and testimonials to learn about other users’ experiences. | |

| -Select manufacturers with a record of high-quality machines and top-notch customer service. | |

| Quality and regulatory compliance | -Ensure the machine complies with relevant regulatory and quality standards. |

| Flexibility for future needs | -Estimate your soft gel production processes’ needs for expansion and growth. |

| -Can the machine you’ve selected be readily modified or expanded to meet the needs of emerging products or greater production volumes? |

Conclusion

When evaluating the capacity of a soft gel encapsulating machine, it’s important to consider your specific production requirements, desired production timeline, and anticipated growth. You can consult with experts such as Jangli Equipment so that we can help you determine the most suitable machine capacity for your needs.

You’ll make an informed choice by understanding the capacity of soft gel encapsulation machines and considering all the factors I’ve mentioned in this article.