Discover How to Prevent Lecithin Leakage During the Softgel Production Process Today!

Lecithin Softgel Capsules

Do you want to get smarter, boost cognitive performance, and attain smoother skin? Lecithin softgel capsules are the solution you need! Also known as lecitina, or ovolecithin, this supplement boosts cellular function, and prevents chronic disease by releasing potent antioxidants. These are just a few of lecithin’s health benefits. Wuxi Jangli Machinery Company Ltd provides a convenient way to consume this useful supplement by packing it into softgel capsules. Read on to discover more about this natural compound, its benefits, and why you should include lecithin softgels in your daily diet!

Components of Lecithin

Fundamentally, lecithin is a group of yellow-brown oily substances that are present in animal, and plant tissues as well as egg yolk. The components of this material include phosphoric acid, choline, fatty acids, glycerol, glycolipids, triglycerides, and phospholipids. Lecithin is essential in cell membrane development and serves as alveolar surfactant. This fatty substance also esterifies cholesterol lipoproteins, and enhances bile production. Lecithin is also a source of lipid messengers such as lysophosphatidylcholine, phosphatidic acid, diglycerides, lysophosphatidic acid, and arachidonic acid.

Functions of Lecithin

Upon consumption, lecithin is a highly beneficial health food. Choline is its main component, and an important daily nutrient for the human body. Lecithin also emulsifies, and decomposes oil. In doing so, it promotes blood circulation, and improves serum quality. Furthermore, it eliminates peroxides, blood lipids, and high cholesterol. Lecithin has so many nutritional benefits that it is usually added to infant formula under recommendation of the U.S. Food and Drug Administration (FDA)!

Industrial Production of Lecithin Softgel Capsules

In today’s commercial supplement industry, lecithin mainly exists in the form of soft capsules. All major health care product manufacturers have their own lecithin products. As an industrial food processor, you can profit from the large market size of lecithin soft capsules by investing in a lecithin softgel encapsulation machine from the Wuxi Jangli Company!

The industrialized production of lecithin soft gelatin capsules involves the insertion of lecithin raw material into a gelatin ribbon using a softgel encapsulation machine. However, the gelatin ribbon contains water, and lecithin exhibits notable water absorption. As a result, this nutrient will absorb a certain amount of water from the gelatin ribbon. This can lead to leakage of lecithin softgel capsules after long-term storage. Therefore, many factories face the challenge of avoiding leakage during industrialized large-scale production of lecithin softgels.

Lecithin Softgel Leakage Solved!

To understand our solution, note that the production process of softgel capsules begins with the production of raw materials, then softgel encapsulation, and finally the drying of softgel capsules.

1. Gelatin Melting Procedure and Craft Improvement

- Begin by selecting good quality gelatin powder in order to improve the seam rate of your softgel capsules. We recommend using bone gelatin. Moreover, the bloom of gelatin powder should be 180 or 200. In addition to that, the melting temperature should be around 65°C. You can also refer to the suggestions given by the gelatin manufacturer.

- Slightly adjust the gelatin recipe. Normally, the standard gelatin formula consists of 1 part water to 1 part gelatin powder (1:1). For lecithin softgel capsule production, we suggest an increase in the proportion of gelatin powder. Therefore, adjust the ratio of water to gelatin powder to 1:1.1 or 1:1.2. While doing so, note that this ratio can be adapted to the internal production process of your factory.

- After the gelatin solution is produced and transferred to the gelatin holding tanks, (gelatin service tanks), it needs to be transported to the softgel capsule machine as soon as possible for the subsequent production process. Do not keep the ready-made gelatin solution in the gelatin service tanks, (gelatin holding tanks) too long or overnight.

2. Lecithin Softgel Encapsulation Procedure Improvement

1) Adjustment of Gelatin Ribbon Thickness

During ordinary soft capsule production, the gelatin ribbon thickness is kept between 0.7mm – 0.8mm. However, during lecithin soft capsule production, we recommend that the gelatin ribbon thickness is kept between 0.8mm – 0.9mm. A thicker gelatin ribbon is essential to improve the seam rate of lecithin softgels.

2) Softgel Die Roller Set Craft Improvement

To solve the lecithin softgel capsule leakage problem, the Wuxi Jangli Machinery Company designed a special die roller. This innovative component has a larger upper cutting surface – See pictures.

According to our observations, lecithin soft capsules mainly leak at the upper seam. That’s because softgel capsules which have a low seam rate, are most likely to leak from the upper seam. In order to improve the upper seam’s rate, we redesigned the cutting area on the lecithin softgel capsule die rollers. Increasing the upper cutting area fixes the gelatin ribbon, and drastically improves the seam rate!

3) Improvement of the Injection Segment (wedge) Craft for the Die Rollers

A very important factor is the temperature of the injection wedge (segment). It is crucial to the softgel capsule seam rate. The Wuxi Jangli Machinery Company has designed a wider, and larger wedge (segment) for lecithin encapsulation. The wide design makes the injection wedge (segment) heat up more evenly, thus improving the seam rate. At the same time, it is recommended that the segment (wedge) used in the production of lecithin also implements the direct injection method.

4) Improvement of the Pre-drying Process of Lecithin Soft Capsules

Softgel capsules need to be pre-dried in a shaped tumbler after encapsulation. We suggest that the rotating speed of the pre-drying tumble dryer should not be too fast. Essentially, 15rpm – 20rpm (Rotations Per Minute) is enough. In addition to that, the tumbler basket should not be loaded to more than 50% of its maximum loading capacity. This prevents extrusion impact that could result in leaking softgel capsules. Along with this, the setting drying time should be a little longer than ordinary soft capsules. We recommend a qualitative drying time of at least 40 minutes.

3. Lecithin Softgel Drying Procedure and Craft Improvement

Lecithin soft gelatin capsules require a specific temperature, and humidity during the drying process. However, it is not true that the lower the humidity, the better. If the humidity is too low, the surface of the softgel is likely to dry first, resulting in the inside of the soft capsule not being completely dry. This situation increases the hygroscopicity of the contents. Therefore, we suggest letting the inside, and outside of the lecithin soft capsule dry simultaneously under slightly higher humidity conditions. This actively prevents leakage due to the hygroscopic properties of the contents during the subsequent storage of the lecithin soft capsules.

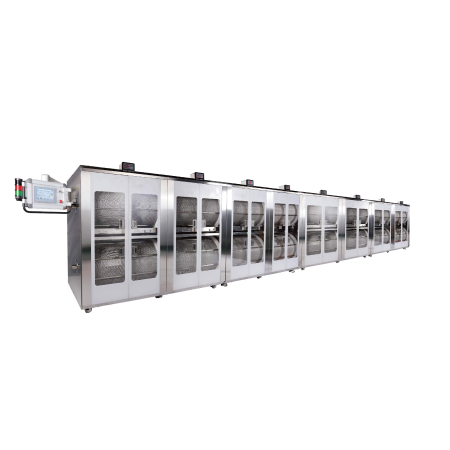

To accomplish this precise drying procedure, we recommend the Wuxi Jangli Company’s JLGZ70-I Intelligent Tumble Dryer. The intelligent tumbler has a built-in dehumidifier. The temperature, and humidity of each drying basket can be independently controlled. In addition to that, temperature, and humidity can be adjusted separately. This unique characteristic is highly conducive to the uniform drying of lecithin capsules. At the same time, the drying program can be set, so that the drying process is completed automatically without human intervention! According to our current experience, and customer feedback, the humidity is set at 26% for four hours in the first stage, 24% for four hours in the second stage, and 22% for four hours in the third stage. Set the humidity at 20%, and then dry until the lecithin soft capsule reaches to the standard.

Prevent Lecithin Softgel Capsule Leakage Permanently

Lecithin plays a significant role in promoting our health, and wellness. In addition to preventing serious diseases, lecithin also delivers a soft complexion. This nutritional supplement is consumed easily in the form of soft gelatin capsules. However, many manufacturers have noticed lecithin leakage during industrialized large-scale production of lecithin softgels. After in-depth investigation, collaboration with numerous softgel manufacturers, experience with softgel capsule machines, and equipment production, as well as technical improvement, we created a four-point, comprehensive solution for lecithin softgel leakage prevention! Furthermore, at the Wuxi Jangli Machinery Company, we innovated the JLGZ70-I Intelligent Tumble Dryer to help ensure optimum temperature, and humidity during the drying process. Apply our solution, and invest in our purpose-built dryer to manufacture leakproof lecithin soft gelatin capsules today!

Reference Links

https://www.recsmedix.com/product/lecithin-softgel/

https://www.jangli-equipment.com/product/jlgz70-i-intelligent-tumble-dryer/