+86 18262272207

[gtranslate]

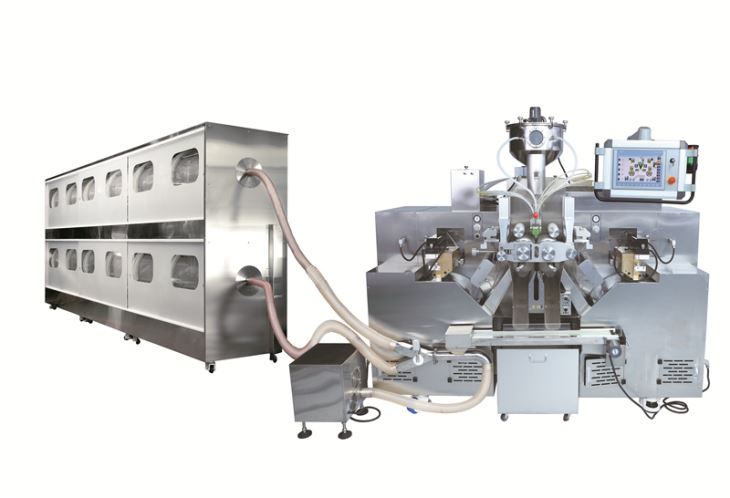

The biggest softgel encapsulation system for large-scale production

Introduction for soft gelatin machine

Softgel gelatin machine is our main machine. It is also the main machine for making different type softgel capsules. The quality of softgel capsules products are main based on the qualify machine. Good machine will have good product.

One set main machine will mainly include gelatin ribbon maker, injection pump and encapsulation parts. Based on more than 15 years machine making experience, we know how to make a good machine also combined with advanced technology.

Specifications:

|

Technical Specification |

JLH-300II |

|

Output |

287640/h(8#OV; 6rpm) |

|

Die Roll Size |

Φ200×300mm |

|

Die Roll Speed |

0-8rpm |

|

Plunger |

20 sets, 24sets and 34 sets available |

|

Feeding Range |

0-2mL |

|

Feeding Variance |

±1.5% |

|

Overall Size |

2200*1000*1900 |

|

Overall Weight |

1800Kg |

|

Total Power |

15kw |

|

Points |

Some Modification is available based on your specific requirement. Automatic thickness control; Automatic die alignment; Automatic injection time |

Advanced technology and Feature show

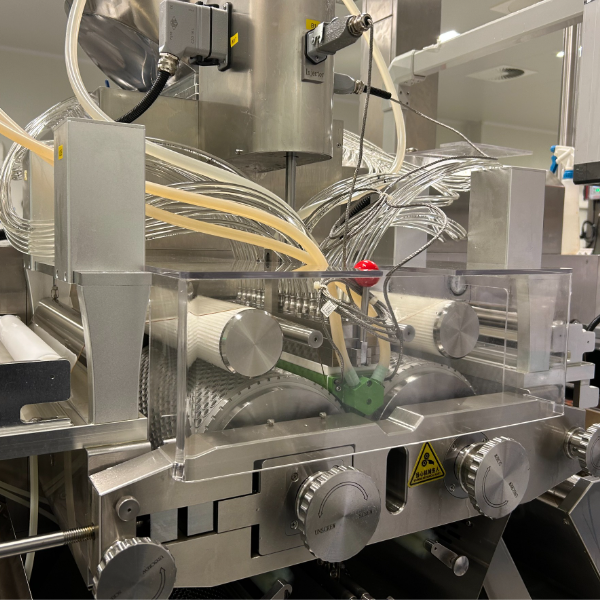

Gelatin ribbon maker:

This parts also include some small parts. It is spreader box, cooling drum and gelatin ribbon lubrication system.

Spreader box:It installed with automatic ribbon thickness motor, which will easy to control thickness accurately and also save lot of cost.

Cooling drum: Based on many clients requirement, our machine drum not only can be cool but also can be heated. The temperature can be control from 15~65℃.

Lubrication system: The lubrication oil quantity for inside and out side of gelatin ribbon can be controlled independently accurately with 4 sets flowmeter from Japan.

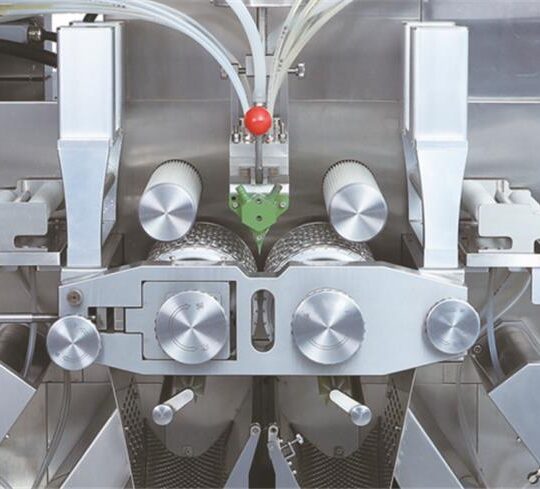

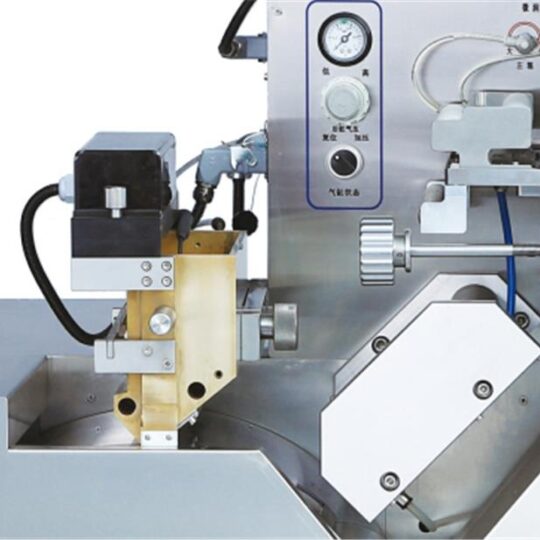

Injection Pump:

The filling weight for the softgel capsules is the most important for the quality of final softgel capsule product. The filling weight accuracy is depended on the accuracy of injection pump. It is the heart for the soft gelatin machine. We can supply different injection pump with different plunger (6~34Plungers) based on your requirement.

Above the Injection pump is the material box. It designed with two-layer structure with water heating. It also have mixer, which make the material solution more evenly. In order to clean easily and follow GMP requirement, the box is made into cylinder design.

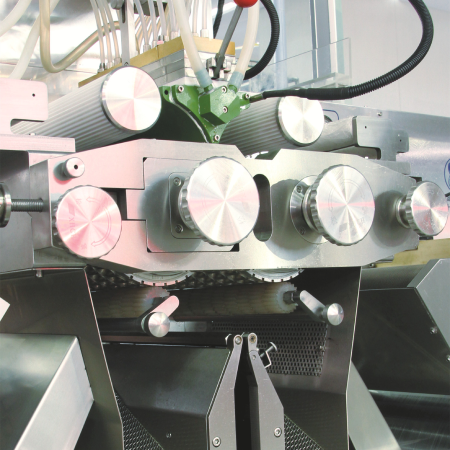

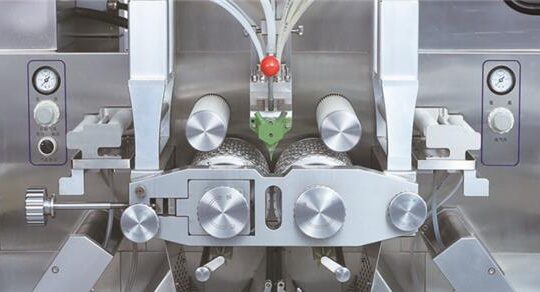

Encapsulation part:

It is the part that make the different product and form the softgel capsules early. The mold for soft gelatin machine called die roll. The die roll has specific design based on the production process. Automatic die alignment, automatic injection time

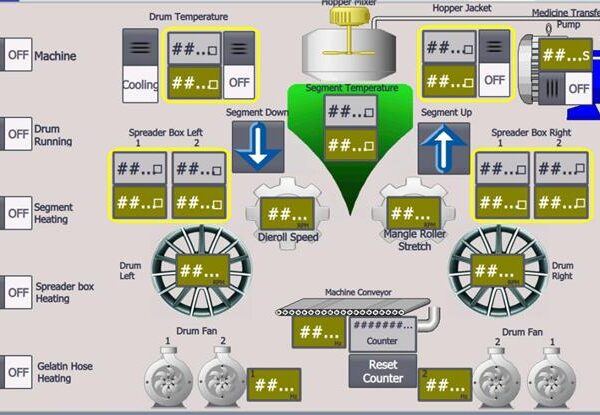

Control system:

A human machine interface will control all those parts into one complete system and work smoothly. The touch screen is designed following the machine production process, which will be easy to operate and lean. By the way, any error happen during working, the machine will show a alarm and show where is wrong and what happened and also the reason. It is very intelligent controlling system based on SIEMENS system and PLC drive.

Grow Your Business With Jangli

Contact us for more details